Kugamuchirwa kumawebhusaiti edu!

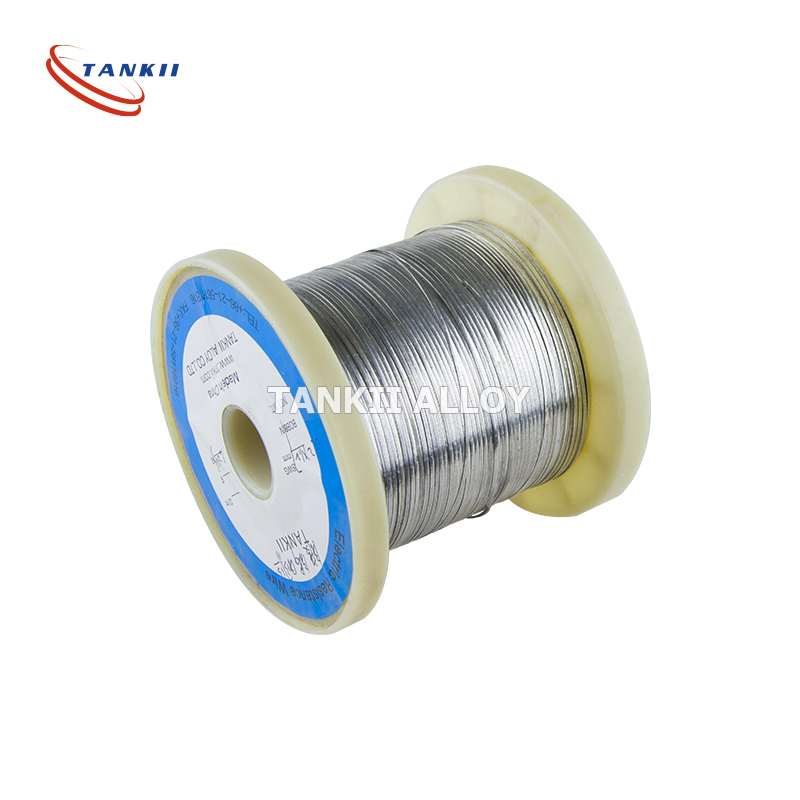

Flat Wire Nicr/Fecral Alloy Ni80cr20, nicr7030, nicr6015,0cr25al5,0cr23al5,0cr21al6nb

| Condition | Bright / Acid White / Oxidied Ruvara |

| Diameter | 0.018mm-1.6mm muSpool, 1.5mm-8mm muCoil, 8mm-60mm muRod |

| Round Wire Diameter | 0.018mm - 10mm |

| Ribhoni | Ukobvu 0.01-2mm, Upamhi 0.5-5mm |

| Strip | Ukobvu 0.001-7mm, Upamhi 1-450mm |

| Giredhi | 1Cr13Al4, 0Cr25Al5, 0Cr21Al6,0Cr23Al5, 1Cr20Al3,0Cr21Al6Nb, 0Cr27Al7Mo2 |

| Production Standard | ASTM B603, DIN 17470, JIS C2520, GB/T 1234 |

| Hunhu | Kuita kwakadzikama, Anti-Oxidation, Corrosion Resistance, High Temperature Kugadzikana, Yakanakisa Coil-Kugadzira Kugona, Yakafanana uye Yakanaka Surface Mamiriro isina Spots |

| Usage | Resistance Heating Elements;Material in Metallurgy;Household Appliances; Mechanical Manufacturing uye mamwe maindasitiri. |

| Nichrome's metallurgical structure inovapa plastiki yakanaka kwazvo kana kuchitonhora | |

| Zvatiri Zvakanakira | Hunhu Hwepamusoro, Nguva Yekutumira Ipfupi, Diki MOQ |

Hunhu Hukuru hweNichrome Resistance Waya:

| Alloy Nomenclature Performance | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 1Cr20Al3 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

|---|---|---|---|---|---|---|---|---|

| Main Chemical composition | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| Re | mukana | mukana | mukana | mukana | mukana | mukana | mukana | |

| Fe | Zorora | Zorora | Zorora | Zorora | Zorora | Zorora | Zorora | |

| Nb0.5 | Mo1.8-2.2 | |||||||

| Max.kuenderera mberi sevhisi temp.che element | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Kuramba pa20ºC (μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| Density (g/cm3) | 7.40 | 7.10 | 7.16 | 7.25 | 7.35 | 7.10 | 7.10 | |

| Thermal conductivity(KJ/m·h·ºC) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| Coefficient yemitsara yekuwedzera (α×10-6/ºC) | 15.4 | 16.0 | 14.7 | 15.0 | 13.5 | 16.0 | 16.0 | |

| Melting point (approx.)( ºC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Kusimba kwesimba (N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| Kurebesa pakuputika (%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Kusiyana kwenzvimbo(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| Kubhenda frequency (F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| Kuoma (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Nguva Yesevhisi Inoenderera (Maawa/ ºC) | - | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

| Micrographic chimiro | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Nyora meseji yako pano uye titumire kwatiri