Tinokugamuchirai kumawebhusaiti edu!

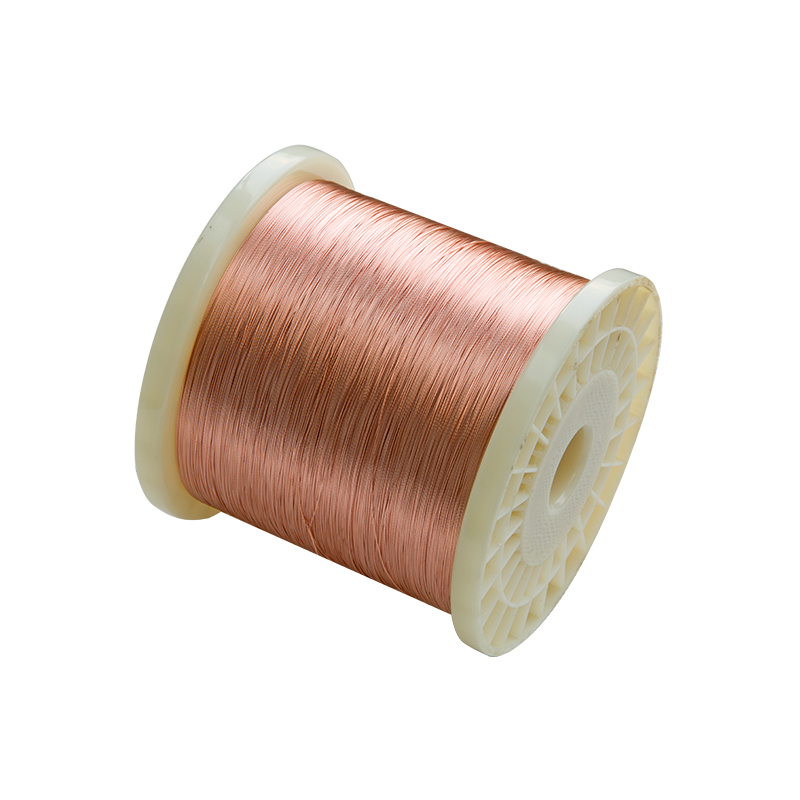

Tankii 1.0mm Waya yemhangura yakachekwa T2 Tsvuku yemhangura inodzivirira oxidation uye inofambisa zvakanaka

Tsananguro yeChigadzirwa

Waya yemhangura ine magaba ye1.0mm (Muviri wemhangura tsvuku, 3-5μ Tin Coating)

Pfupiso yeChigadzirwa

Semuchina wemagetsi unoshanda zvakanyanya kubva kuTankii Alloy Material,Waya yemhangura yakagadzirwa ne 1.0mmInobatanidza mabhenefiti maviri makuru: conductivity yakanyanya yemhangura tsvuku chaiyo (T2 grade) uye dziviriro yekudzivirira ngura ye 3-5μ tin coating chaiyo. Yakagadzirwa kuburikidza ne Huona's advanced hot-dip tinning process—yakashongedzerwa nekutarisa ukobvu hwenguva chaiyo uye kudzora tembiricha—waya iyi inoita kuti tin layer inamire zvakaenzana ku 1.0mm solid copper core, isina makomba kana madonhwe matete. Inogadzirisa marwadzo maviri makuru ewaya yemhangura isina chinhu: kudzikira kwe conductivity inokonzerwa ne oxidation uye kusagona kusvetukira zvakanaka, zvichiita kuti ive chinhu chikuru chekubatanidza magetsi kunoda kugadzikana kwenguva refu, nyore kusangana, uye kuramba nzvimbo dzine hunyoro/maindasitiri.

Zvitupa zveStandard & Material

- Giredhi reMutyairi: T2 mhangura tsvuku chaiyo (inoenderana neGB/T 3956-2008; yakaenzana neASTM B33, IEC 60288 Kirasi 1)

- Standard yeKuputira Tin: GB/T 4910-2009, IEC 60317-2 (isina mutobvu: Pb ≤0.005%, Sn ≥99.9%)

- Zvitupa zveHunhu: Kutevedzera RoHS 2.0, ISO 9001 quality management system, kubvumidzwa kwekuyedzwa kwezvakatipoteredza kweSGS

- Mugadziri: Tankii Alloy Material (makore anopfuura gumi nemashanu eruzivo rwekugadzirisa conductor yemhangura)

Zvakanakira Kushanda Kwakakosha

1. Mutyairi wemhangura tsvuku wakachena: Kufambisa kwemhepo kusingaenzaniswi

- Kufambisa Kwemagetsi: ≥98% IACS (20℃), inodarika mhangura yakasanganiswa (semuenzaniso, CuNi alloys: ~20% IACS) uye aruminiyamu (61% IACS). Inovimbisa kudzikira kushoma kwemagetsi mumasekete ane voltage shoma (semuenzaniso, waya dzemotokari dze12V, tambo dze USB dze5V) uye kutumira kwechiratidzo nekukurumidza kwemasensa.

- Kushanda Kwemakanika: Kureba ≥30% (25℃) uye simba rekudhonza ≥200 MPa. Inogona kutsungirira kukotama kunodzokororwa (kuyedzwa kwekukombama kwe180° ≥10 kasingatyoke) kwewaya munzvimbo dzakamanikana (semuenzaniso, zvikamu zvemukati memudziyo, kubatana kwePCB).

2. 3-5μ Kuvhara Tin Yakakodzera: Dziviriro Yakanangwa

- Chipingamupinyi Chekudzivirira Kuokisijeni: Chidimbu chakasimba chetin chinovhara mhepo/hunyoro kuti isabatane nemhangura, zvichidzivirira kuumbwa kwecopper oxide inofambisa mhepo (CuO/Cu₂O). Kunyangwe muhunyoro hwe80% kwemwedzi gumi nemiviri, waya inochengetedza ≥97% yehunyoro hwekutanga (zvichienzaniswa nemhangura isina chinhu: inodonha kusvika 85% mumwedzi mitatu).

- Kukwanisa Kutengesa Kwakawedzerwa: Kunyunguduka kwakaderera kweTin (232℃) kunogonesa "kunyorovesa ipapo ipapo" panguva yekusonera - hapana kutsvaira kana flux activation inodiwa. Inoderedza nguva yekubatanidza PCB ne40% zvichienzaniswa nemhangura isina chinhu (inoda kubviswa kweoxide kuburikidza nekusonera/makemikari).

- Dhizaini Yekukora Kwakaringana: 3-5μ ukobvu hunodzivirira zvinhu zviviri zvakanyanyisa: machira matete (<3μ) haakwanise kuvhara zvikanganiso zvemhangura, nepo machira matete (>5μ) achiita kuti waya itsvedze (inowanzotsemuka kana ichikotama).

Magadzirirwo ehunyanzvi

| Paramita | Kukosha Kwakadzama |

| Dhayamita Yezita (Zvose) | 1.0mm (kondakita: ~0.992-0.994mm; simbi yekufukidza: 3-5μ) |

| Dhayamita Kushivirira | ± 0.02mm |

| Ukobvu hweTin Coating | 3μ (pasi) – 5μ (yakanyanya); ukobvu hwakafanana: ≥95% (hapana gwapa <2.5μ) |

| Kufambisa Kwemagetsi (20℃) | ≥98% IACS |

| Simba reKusimba | 200-250 MPa |

| Kureba paKuzorora | ≥30% (L0=200mm) |

| Kunamatira kweTin | Hapana kukweshwa/kupwanyika mushure mekukombama kwe180° (radius=5mm) + bvunzo yetepi (tepi ye3M 610, hapana tin residue) |

| Kuramba Kuora | Inopasa bvunzo yeASTM B117 salt spray (48h, 5% NaCl, 35℃) - hapana ngura yakatsvuka, tin inoputika |

| Kushanda Tembiricha Range | -40℃ (kuchinjika kwekupisa kwakaderera, hapana kutsemuka) kusvika 105℃ (kushandiswa nguva dzose, hapana kunyunguduka kwetin) |

Kuwanikwa Kwechigadzirwa & Kugadzirisa

| Chinhu | Tsanangudzo |

| Fomu Rekupa | Kondakita yakasimba (yakajairwa); kondakita yakasungirirwa (yakajairwa: 7/0.43mm, 19/0.26mm) |

| Kugadziriswa kweSpool | 500m/1000m pamudziyo wega wega (zvinhu zvemudziyo: ABS plastic, dhayamita: 200mm, gomba guru: 50mm) |

| Kupedzisa Kwepamusoro | Tini inopenya (yakajairika); tini isina kupenya (yakagadzirirwa kushandiswa kudzivirira kupenya) |

| Kurapa Kwekuwedzera | Kudzivirira kwakasarudzika (PVC/XLPE/Silicone, ukobvu: 0.1-0.3mm, ruvara: dema/tsvuku/bhuruu) |

| Kurongedza | Bhegi refoiri realuminium rakavharirwa ne vacuum (rinodzivirira hunyoro) + katoni yekunze (ine desiccant, inodzivirira kukanganiswa) |

Maitiro Akajairika Ekushandisa

- Midziyo yemumba: Waya dzemukati dzemuchina wekuwachisa (dzinodzivirira hunyoro), mafiriji (dzinochinjika zvishoma pakupisa), uye maovheni e microwave (dzinodzivirira kupisa kusvika ku105℃).

- Zvemagetsi zveMotokari: Zviteshi zvekubatanidza mabhatiri emota (anodzivirira ngura), waya dze sensor (signal yakagadzikana), uye masisitimu e infotainment ari mumota (kudonha kwevoltage yakaderera).

- PCB & Zvemagetsi zveVatengi: Kubatanidza maburi nemaburi emabhodhi eArduino/Raspberry Pi, maconductor eUSB-C cable, uye waya dze LED strip (zviri nyore kugadzira).

- Kudzora Maindasitiri: Kuisa waya dzemapaneru ePLC (kuramba hunyoro mumaindasitiri) uye magetsi ane simba shoma (kurasikirwa nesimba kushoma).

- Zvishandiso Zvekurapa: Waya dzemukati dzezvishandiso zvekuongorora zvinotakurika (zvisina mutobvu, zvinoenderana nezvinodiwa nemuviri) uye pombi diki dzekurapa (dzinochinjika).

Kuvimbiswa Kwemhando Yepamusoro kubva kuTankii Alloy Material

Boka rega rega rewaya yemhangura ine 1.0mm inoongororwa zvinhu zvitatu zvakakosha:

- Kuedzwa kweKukora kweTin: X-ray fluorescence (XRF) analyzer (yakarurama: ± 0.1μ) – 5 points yekutora sampuli pa spool imwe neimwe.

- Kuedzwa kweKufambisa: Muedzi wekuongorora ane mapoinzi mana (kururama: ± 0.5% IACS) – sampuli nhatu pabatch imwe neimwe.

- Kuedzwa kweMechaniki: Muchina wekuyedza wepasi rose (kudhonza/kureba) + muyedzi wekukombama (kunamatira) – 2 sampuro pabhechi.

Sampuli dzemahara (kureba 1m, zvidimbu 2-3 padanho rega rega) uye Mishumo yeKuedza Zvinhu (MTR) yakadzama inowanikwa kana ukakumbira. Chikwata chedu chehunyanzvi chinopa rutsigiro rwemunhu mumwe chete kune zvinodiwa nevatengi (semuenzaniso, kusarudzwa kwezvinhu zvinodzivirira kupisa kwekushandisa pakupisa kwakanyanya, dhizaini yeconductor yakamiswa yewaya inochinjika).

Nyora meseji yako pano woitumira kwatiri

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro