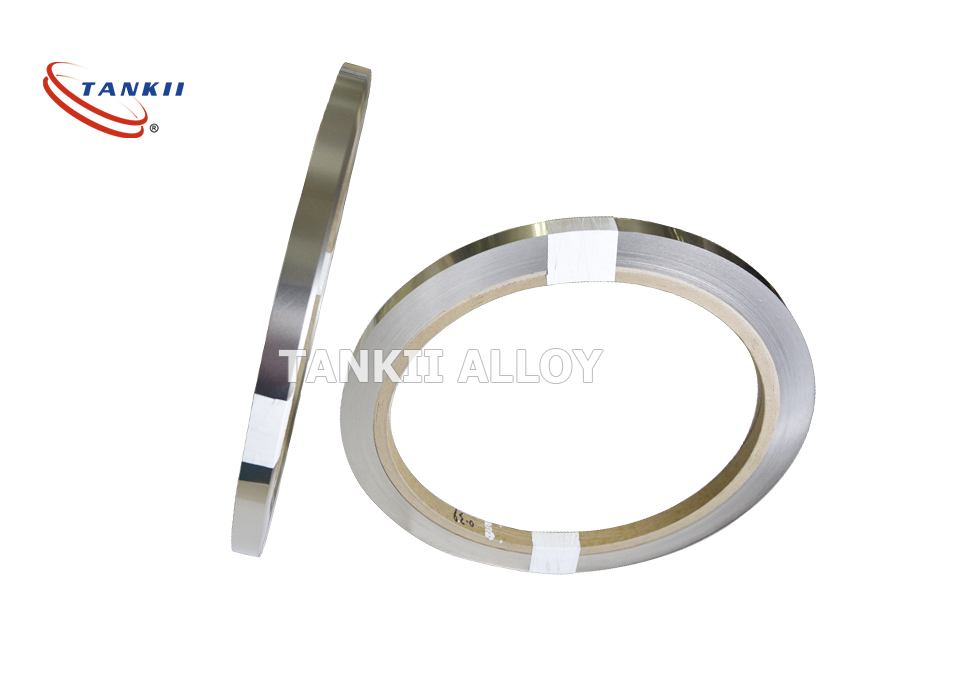

Strip Coil ye0.05mm Hukobvu FeCrAl resistance waya

FeCrAl AlloyFoil/ Strip Coil 0.05mm Hukobvu hweMetallic Huchi Substrates

Iyo yakakwira aluminium yemukati, pamwe neyakakura chromium yemukati inoita kuti tembiricha yekuyera iwedzere kusvika 1425 C (2600F); Pasi pemusoro wemusoro wekudzivirira kupisa, izviFeCrAl alloys inofananidzwa neanowanzo shandiswa Fe uye Ni base alloys. Sezvinoonekwa kubva patafura iyo, iyoFeCrAl alloys ane zvivakwa zvepamusoro kana zvichienzaniswa nemamwe alloys munzvimbo zhinji.

Izvo zvinofanirwa kucherechedzwa kuti, panguva yekuchinjisa tembiricha mamiriro, iyo yttrium yekuwedzera kune AF alloy iyo inozivikanwawo seFecralloys alloys, inovandudza kunamatira kweinodzivirira oxide, zvichiita kuti hupenyu hwesevhisi hwezvikamu muAF alloy hurebe kupfuura iyo yegiredhi A-1.

Fe-Cr-Al alloy waya dzakagadzirwa nesimbi chromium aluminium base alloys ine zvidiki zvezvinoita zvinhu zvakaita seyttrium uye zirconium uye inogadzirwa nekunyungudika, kukungurutswa kwesimbi, kuforoma, kudhirowa, kudhirowa, kurapwa kwepamusoro, kuyedza kudzora kuyedza, nezvimwe.

Fe-Cr-Al waya yakaumbwa nenzira yekumhanyisa otomatiki yekutonhodza muchina iyo simba remagetsi rinodzorwa nekombuta, inowanikwa sewaya uye ribhoni(strip).

Zvimiro uye zvakanakira

1. Yakakwirira uchishandisa tembiricha, iyo yakanyanya kushandisa tembiricha inogona kusvika 1400C (0Cr21A16Nb, 0Cr27A17Mo2, nezvimwewo)

2. Yakaderera tembiricha coefficient yekupikisa

3. Kuderera kwekuwedzera kwekushisa kwekuwedzera kwehuwandu kupfuura Ni-base super-alloys.

4. High magetsi resistivity

5. Kuramba kwakanaka kwekuora pasi pekushisa kwepamusoro, kunyanya pasi pemhepo ine sulfides

6. Mutoro wepamusoro wepamusoro

7. Creep-resistant

8. Mutengo wepasi mbishi-material, Lower density uye mutengo wakachipa zvichienzaniswa newaya yeNichrome.

9. Superior oxidation resistance pa800-1300ºC

10. Hupenyu hurefu hwebasa

Kuumbwa kwe metastable alumina phases nekuda kweiyo oxidation yekutengeseranaFeCrAl alloywaya (0.5 mm ukobvu) patembiricha dzakasiyana uye nguva dzakaongororwa. Samples aive isothermally oxidised mumhepo achishandisa thermogravimetric analyzer (TGA). Iyo morphology yemasampuli ane oxidised yakaongororwa pachishandiswa Electronic Scanning Electron Microscope (ESEM) uye X-ray pamusoro pekuongororwa kwepamusoro kwakaitwa pachishandiswa Energy Dispersive X-Ray (EDX) analyzer. Iyo nzira yeX-Ray Diffraction (XRD) yakashandiswa kuratidza chikamu chekukura kweoxide. Chidzidzo chese chakaratidza kuti zvaigoneka kukura yakakwirira-yepamusoro nzvimbo gamma alumina paneFeCrAl alloypawaya kana yaiswa oxidised kupfuura 800°C kwemaawa akati wandei.

| Iron Chrome Aluminium | |||||||

| OCr25Al5 | CrAl25-5 | 23.0 | 71.0 | 6.0 | |||

| OCr20Al5 | CrAl20-5 | 20.0 | 75.0 | 5.0 | |||

| OCr27Al7Mo2 | 27.0 | 65.0 | 0.5 | 7.0 | 0.5 | ||

| OCr21Al6Nb | 21.0 | 72.0 | 0.5 | 6.0 | 0.5 | ||

| Iron Chrome Aluminium | ||

| OCr25Al5 | Inogona kushandiswa mumamiriro ekushanda kusvika ku1350 ° C, kunyange zvazvo inogona kuve yakasvibiswa. | Kupisa zvinhu zvehuni dzekushisa kwepamusoro uye zvinopisa zvinopenya. |

| OCr20Al5 | A ferromagnetic alloy inogona kushandiswa patembiricha inosvika 1300°C. Inofanirwa kuvhiyiwa munzvimbo yakaoma kudzivirira ngura. Inogona kuve yakanyungudutswa pakupisa kwakanyanya. | Kupisa zvinhu zvehuni dzekushisa kwepamusoro uye zvinopisa zvinopenya. |

Zvigadzirwa zvikamu

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top