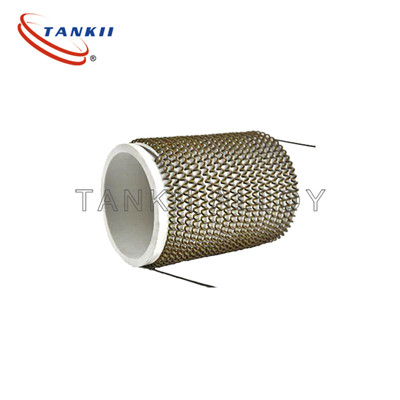

Spring Coil

product tsananguro

Kambani yedu inogadzira yakakwirira-mhando iron-chromium-aluminium uye nickel-chromium yemagetsi ekudziya alloy waya, iyo inotora inodzorwa nekombuta-inodzorwa newaya magetsi uye inokuvadzwa muchimiro nemuchina unomhanya-mhanya otomatiki mhepo. Hunhu hwechigadzirwa ichi: kukwirira kwekushisa kwepamusoro, kupisa nekukurumidza, hupenyu hurefu hwebasa, kushomeka kwakagadzikana, kutsauka kwesimba kudiki, yunifomu yepitch mushure mekutambanudza, inopenya uye yakachena nzvimbo; anoshandiswa zvakanyanya muchoto chemagetsi madiki, muffle furnaces, kudziyisa uye air conditioning midziyo, ovheni dzakasiyana-siyana, Magetsi ekudziya machubhu uye midziyo yemumba, nezvimwe zvakasiyana-siyana zvisiri-standard zvemaindasitiri uye zvevagari vehuni zvinogona kugadzirwa uye kugadzirwa zvinoenderana nezvinodiwa nemushandisi.

| Simba W | Voltage V | Diameter mm | OD mm | Length (Reference) mm | Wmasere g |

| 300 | 220 | 0.25 | 3.7 | 122 | 1.9 |

| 500 | 220 | 0.35 | 3.9 | 196 | 4.3 |

| 600 | 220 | 0.40 | 4.2 | 228 | 6.1 |

| 800 | 220 | 0.50 | 4.7 | 302 | 11.1 |

| 1000 | 220 | 0.60 | 4.9 | 407 | 18.5 |

| 1200 | 220 | 0.70 | 5.6 | 474 | 28.5 |

| 1500 | 220 | 0.80 | 5.8 | 554 | 39.0 |

| 2000 | 220 | 0.95 | 6.1 | 676 | 57.9 |

| 2500 | 220 | 1.10 | 6.9 | 745 | 83.3 |

| 3000 | 220 | 1.20 | 7.1 | 792 | 98.3 |

Kupisa uye kuumbwa kwemakemikari yewaya yekupisa

| Giredhi | Max. Coti uous Operating Temper. | Cr% | Ni% | Al% | Fe% | Re% | Nb% | Mo% |

| Cr20Ni80 | 1200 ℃ | 20~23 | Bal. |

|

|

|

|

|

| Cr30Ni70 | 1250 ℃ | 28~31 | Bal. |

|

|

|

|

|

| Cr15Ni60 | 1150 ℃ | 15~18 | 55~61 |

| Bal. |

|

|

|

| Cr20Ni35 | 1100 ℃ | 18~21 | 34~37 |

| Bal. |

|

|

|

| TANKII APM | 1425℃ | 20.5~23.5 |

| 5.8 | Bal. | / |

|

|

| 0Cr27Al7Mo2 | 1400 ℃ | 26.5~27.8 |

| 6~7 | Bal. |

|

| 2 |

| 0Cr21Al6Nb | 1350 ℃ | 21~23 |

| 5~7 | Bal. |

| 0.5 |

|

| 0Cr25Al5 | 1250 ℃ | 23~26 |

| 4.5~6.5 | Bal. |

|

|

|

| 0Cr23Al5Y | 1300 ℃ | 22.5~24.5 |

| 4.2~5.0 | Bal. |

|

|

|

| 0Cr19Al3 | 1100 ℃ | 18~21 |

| 3~4.2 | Bal. |

|

|

|

Huru tekinoroji zvivakwa zveFeCrAl alloy waya:

①Tembiricha yekushandisa yakakwira, tembiricha yekushandisa yesimbi-chromium aluminium alloy waya mumhepo inogona kusvika 1300 ℃;

②Hupenyu hurefu hwebasa;

③Mutoro unobvumirwa wepamusoro wakakura;

⑤Iyo chaiyo giravhiti idiki pane nickel-chromium alloy; ④Iyo oxidation kuramba yakanaka, uye iyo AI2O3 firimu yakaumbwa mushure meiyo oxidation ine yakanaka makemikari kuramba uye yakakwirira resistivity;

⑥High resistivity;

⑦Kuramba kwakanaka kwesarufa;

⑧Mutengo wakaderera zvakanyanya pane wenickel-chromium alloy;

⑨Chakashata ndechekuti tembiricha painowedzera, inoratidza plastiki, uye simba pakupisa kwakanyanya kwakadzikira.

Hunhu hwenickel-chromium electric stove waya ndeidzi:

① Simba repamusoro pakupisa kukuru;

②Kutonhorera pasi mushure mekushandisa kwenguva refu, zvinhu hazvizove brittle;

③Kuburitsa kweNi-ming alloy yakazadzwa oxidized kwakakwira kupfuura yeFe-Cr-Al alloy;

④Hapana magineti;

⑤Kunze kwesarufa mamiriro ekunze, ine zvirinani corrosion resistance

Zvigadzirwa zvikamu

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top