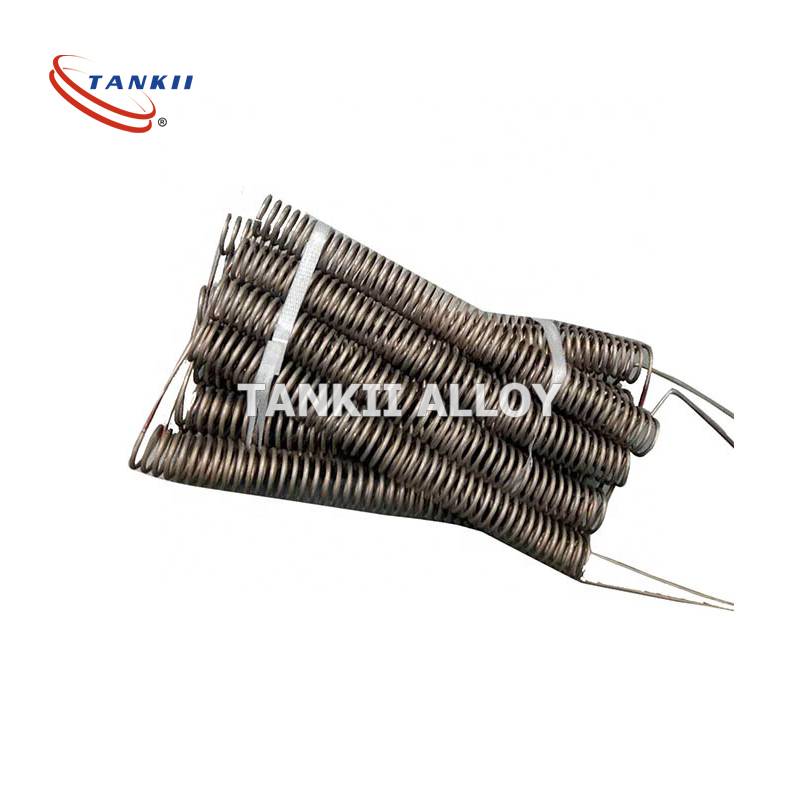

Spiral Electric Resistor CuNi Alloy 1 - 5 Mohm Yezvinhu Zvinodziya zveAir Conditioner

Spiral Electric Resistor Nicr Alloy 1 - 5 Mohm Yekushandisa Air Conditioner Heating Elements

1. Tsananguro Yese Yezvinhu

Constantanisimbi yemhangura-nickel inozivikanwawo seEureka,PamberiuyeChikepeKazhinji ine 55% yemhangura uye 45% nickel. Chinhu chikuru chayo ndechekudzivirira kwayo, iyo inogara iripo pakupisa kwakasiyana-siyana. Mamwe ma alloys ane ma coefficients akafanana ekupisa kwakaderera anozivikanwa, akadai semanganin (Cu).86Mn12Ni2).

Pakuyerwa kwemhando dzakakura kwazvo, 5% (50 000 microstrian) kana kupfuura, annealed constantan (P alloy) ndiyo grid material inowanzo sarudzwa. Constantan muchimiro ichi inonyanya kusarudzwa.ductileuye, muhurefu hwema gauge hwe 0.125 inches (3.2 mm) kana kupfuura, inogona kumanikidzwa kusvika >20%. Zvisinei, zvinofanira kurangarirwa kuti pasi pemhando yepamusoro ye cyclic strains, P alloy icharatidza shanduko inogara iripo pakutenderera kwega kwega, uye inokonzera imwe inoenderana.zerokuchinja kwegeji yekusveta. Nekuda kwehunhu uhwu, uye katsika kekukundikana kwegrid nguva isati yakwana nekusveta kakawanda, P alloy haiwanzo kukurudzirwa kushandiswa kwe cyclic strain. P alloy inowanikwa neSTC nhamba dze 08 ne 40 kuti ishandiswe pasimbi nemapurasitiki, zvichiteerana.

2. Nhanganyaya yeChirimo uye mashandisirwo

Chitubu che torsion chinotenderera, kana kuti vhudzi, chiri muwachi yekuridza alarm.

Chitubu chinopenya. Kana simbi dzacho dzadzvinyirirwa, macoil anotsvedza pamusoro peimwe neimwe, zvichiita kuti kufamba kuenderere mberi.

Zvitubu zveStuart tangi zvakamira zve volute

Kusimba kwesimba mumudziyo wekudzokorora mutsetse wakapetwa.

Bhawa rekutenderera rakamoneredzwa pasi pemutoro

Chitubu chemashizha chiri parori

Zvitubu zvinogona kupatsanurwa zvichienderana nekuti simba remutoro rinoshandiswa sei kwavari:

Chitubu chekusimba/kutambanudza - chitubu chakagadzirirwa kushanda nechinhu chinosimba, saka chitubu chinotambanuka sezvo mutoro uchiiswa pachiri.

Chitubu chekudzvanya - chakagadzirirwa kushanda nemutoro wekudzvanya, saka chitubu chinopfupika kana mutoro uchiiswa pachiri.

Chitubu cheTorsion - kusiyana nerudzi rwataurwa pamusoro apa umo mutoro uri simba re axial, mutoro unoshandiswa pachitubu cheTorsion isimba re torque kana kuti rinotenderedza, uye mugumo wechitubu unotenderera nepakona sezvo mutoro uchiiswa.

Mutoro unotsigirwa nechitubu unoramba wakafanana panguva yekutsauka kwesimba.

Chitubu chinoshanduka-shanduka - kuramba kwecoil pakuremerwa kunosiyana panguva yekumanikidzwa.

Chitubu chinoshanduka-shanduka chekuomarara - kuramba kwecoil kurodha kunogona kushanduka-shanduka semuenzaniso nesystem yekudzora, mamwe marudzi ezvitubu izvi anosiyanawo nehurefu hwawo zvichipawo kugona kwekufambisa.

Zvinogonawo kupatsanurwa zvichienderana nechimiro chazvo:

Chitubu chakatsetseka - rudzi urwu rwakagadzirwa nesimbi yakatsetseka.

Chitubu chine michina - rudzi urwu rwechitubu runogadzirwa nekushandisa machining bar stock ne lathe uye/kana milling operation pane coiling operation. Sezvo ichigadzirwa nemashini, chitubu chinogona kusanganisira zvimwe zvinhu pamusoro pe elastic element. Chitubu chine michina chinogona kugadzirwa muzviitiko zve load cases zve compression/extension, torsion, nezvimwewo.

Chitubu chenyoka - waya yakakora yakakora - chinowanzoshandiswa mumidziyo yemazuva ano yeumbozha/fenicha.

3.Kuumbwa kweChemical uye Hunhu Hukuru hweCu-Ni Low Resistance Alloy

| Grade yeZvivakwa | CuNi1 | CuNi2 | CuNi6 | CuNi8 | CuMn3 | CuNi10 | |

| Kuumbwa Kwemakemikari Main | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | Bhari | Bhari | Bhari | Bhari | Bhari | Bhari | |

| Tembiricha Yepamusoro Yebasa Rinoenderera Mberi (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Kusimba kwesimba pa20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Kuwanda (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Kufambisa kwekupisa (α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Simba reKusimba (Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Nzvimbo Inofungidzirwa Yekunyunguduka (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Maumbirwo eMicrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Pfuma yeMagineti | kwete | kwete | kwete | kwete | kwete | kwete | |

| Grade yeZvivakwa | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNi44 | |

| Kuumbwa Kwemakemikari Main | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | Bhari | Bhari | Bhari | Bhari | Bhari | Bhari | |

| Tembiricha Yepamusoro Yebasa Rinoenderera Mberi (oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Kusimba kwesimba pa20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Kuwanda (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Kufambisa kwekupisa (α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Simba reKusimba (Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Nzvimbo Inofungidzirwa Yekunyunguduka (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Maumbirwo eMicrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Pfuma yeMagineti | kwete | kwete | kwete | kwete | kwete | kwete | |

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro