Tinokugamuchirai kumawebhusaiti edu!

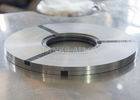

Zvidziviriro Zvakapenya Zvakatsetseka 5mm Upamhi 1Cr13Al4 FeCrAl waya yekudzivirira

1Cr13Al4 FeCrAl alloy Bright Flat Strip/ Wide Strip yekushandiswa neResistors

Fecral Alloys uye Nickel-chromium alloys zvakasarudzwa kuti zvive zvinhu zvinodzivirira resistor yakapinzwa nekuti nickel-chromium alloys dzine resistivity yakakwira yemagetsi iyo inoshandiswa zvakanyanya kune thin film resistor [1, 2]. Kuramba kwepepa re nickel-chrome alloy film ine 20% chromium kunogona kusvika 2-3 kilo ohms uye kuchiri kuramba kwakagadzikana. Tembiricha coefficient 1 of resistance (TCR) ye bulk nickel-chrome alloy inenge 110 ppm/°C. Nekubatanidza silicon nealuminium shoma ne nickel-chromium, kugadzikana kwetembiricha kunovandudzwa zvakanyanya.

Kushandiswa:

Ma resistors akaiswa mubhodhi remagetsi rakadhindwa achava mukana wekuita kuti mapakeji ave madiki uye akavimbika uye mashandiro emagetsi ari nani. Kubatanidza mashandiro e resistor mu laminate substrate kunosunungura nzvimbo yePWB inodyiwa nezvikamu zvakasiyana, zvichiita kuti mashandiro emudziyo awedzere nekuisa zvikamu zvinoshanda zvakanyanya. Nickel-chromium alloys ine resistivity yakakwira yemagetsi, izvo zvinoita kuti zvive nyore kushandisa mumabasa akasiyana-siyana. Nickel nechromium zvinosanganiswa nesilicon nealuminium kuti zvivandudze kugadzikana kwetembiricha uye kuderedza coefficient yekupisa. Layer tete resistive yakavakirwa pa nickel-chromium alloys yakaiswa nguva dzose pamarolls e copper foil kugadzira chinhu chekushandisa embedded resistor. Layer tete resistive film rakaiswa pakati pe copper ne laminate rinogona kuchekwa nenzira yakasarudzwa kuti rigadzire ma resistors akasiyana. Makemikari e etching anowanikwa mumaitiro ekugadzira PWB. Nekudzora ukobvu hwe alloys, sheet resistance values kubva pa25 kusvika 250 ohm/sq. inowanikwa. Pepa iri richaenzanisa zvinhu zviviri zve nickel-chromium mumaitiro azvo ekutema, kufanana, kubata simba, kushanda kwekupisa, kunamira uye kugadziriswa kwekutema.

Ma resistors akaiswa mubhodhi remagetsi rakadhindwa achava mukana wekuita kuti mapakeji ave madiki uye akavimbika uye mashandiro emagetsi ari nani. Kubatanidza mashandiro e resistor mu laminate substrate kunosunungura nzvimbo yePWB inodyiwa nezvikamu zvakasiyana, zvichiita kuti mashandiro emudziyo awedzere nekuisa zvikamu zvinoshanda zvakanyanya. Nickel-chromium alloys ine resistivity yakakwira yemagetsi, izvo zvinoita kuti zvive nyore kushandisa mumabasa akasiyana-siyana. Nickel nechromium zvinosanganiswa nesilicon nealuminium kuti zvivandudze kugadzikana kwetembiricha uye kuderedza coefficient yekupisa. Layer tete resistive yakavakirwa pa nickel-chromium alloys yakaiswa nguva dzose pamarolls e copper foil kugadzira chinhu chekushandisa embedded resistor. Layer tete resistive film rakaiswa pakati pe copper ne laminate rinogona kuchekwa nenzira yakasarudzwa kuti rigadzire ma resistors akasiyana. Makemikari e etching anowanikwa mumaitiro ekugadzira PWB. Nekudzora ukobvu hwe alloys, sheet resistance values kubva pa25 kusvika 250 ohm/sq. inowanikwa. Pepa iri richaenzanisa zvinhu zviviri zve nickel-chromium mumaitiro azvo ekutema, kufanana, kubata simba, kushanda kwekupisa, kunamira uye kugadziriswa kwekutema.

Zvinhu zvechiwanikwa

zvimwe zvigadzirwa zvakatevedzana:

FeCrAl Alloy: OCr15Al5,1Cr13Al4, 0Cr21Al4, 0Cr19Al3, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb,0Cr27Al7Mo2.

NiCr Alloy: Cr20Ni80,Cr30Ni70,Cr20Ni35,Cr20Ni30,Cr15Ni60.

CuNi Alloy: NC003,NC010,NC012,NC015,NC020,NC025,NC030,NC040,NC050,Constantan,6J8/11/12/13/.

Welding waya: ERNiCrMo-3/4/13,ERNiCrFe-3/7,ERNiCr-3/7,ERNiCu-7,ERNi-1, ER70S-6.

Chidimbu cheThermocouple: K,J,E,T,N, S,R,B,KX,JX,EX,TX,NX.

Inconel alloy: Inconel 600,601,617,X-750,625,690,718,825.

Chiumbwa cheIncoloy: Incoloy 800,800H,800HT,825,925.

Hastelloy alloy: HC-276,C-22,C-4,HB,B/2/3,X,N.

Monel Alloy: Monel 400,K500.

Chishongedzo chekupisa kwepamusoro: A-286, Nimonic80A/90, GH131, GH1140, GH36, GH2706, GH2901, GH3625, GH3536, GH4169.

Nhevedzano ye alloy chaiyo: 1J33,3J01,3J9,4J29,4J32.4J33,Invar36,4J45.FeNi50.

Chinwiwa chinopfapfaidza chekupisa: Inconel 625,Ni95Al5,Monel400,45CT,HC-276,K500,Cr20Ni80.

zvimwe zvigadzirwa zvakatevedzana:

FeCrAl Alloy: OCr15Al5,1Cr13Al4, 0Cr21Al4, 0Cr19Al3, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb,0Cr27Al7Mo2.

NiCr Alloy: Cr20Ni80,Cr30Ni70,Cr20Ni35,Cr20Ni30,Cr15Ni60.

CuNi Alloy: NC003,NC010,NC012,NC015,NC020,NC025,NC030,NC040,NC050,Constantan,6J8/11/12/13/.

Welding waya: ERNiCrMo-3/4/13,ERNiCrFe-3/7,ERNiCr-3/7,ERNiCu-7,ERNi-1, ER70S-6.

Chidimbu cheThermocouple: K,J,E,T,N, S,R,B,KX,JX,EX,TX,NX.

Inconel alloy: Inconel 600,601,617,X-750,625,690,718,825.

Chiumbwa cheIncoloy: Incoloy 800,800H,800HT,825,925.

Hastelloy alloy: HC-276,C-22,C-4,HB,B/2/3,X,N.

Monel Alloy: Monel 400,K500.

Chishongedzo chekupisa kwepamusoro: A-286, Nimonic80A/90, GH131, GH1140, GH36, GH2706, GH2901, GH3625, GH3536, GH4169.

Nhevedzano ye alloy chaiyo: 1J33,3J01,3J9,4J29,4J32.4J33,Invar36,4J45.FeNi50.

Chinwiwa chinopfapfaidza chekupisa: Inconel 625,Ni95Al5,Monel400,45CT,HC-276,K500,Cr20Ni80.

Nyora meseji yako pano woitumira kwatiri

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro