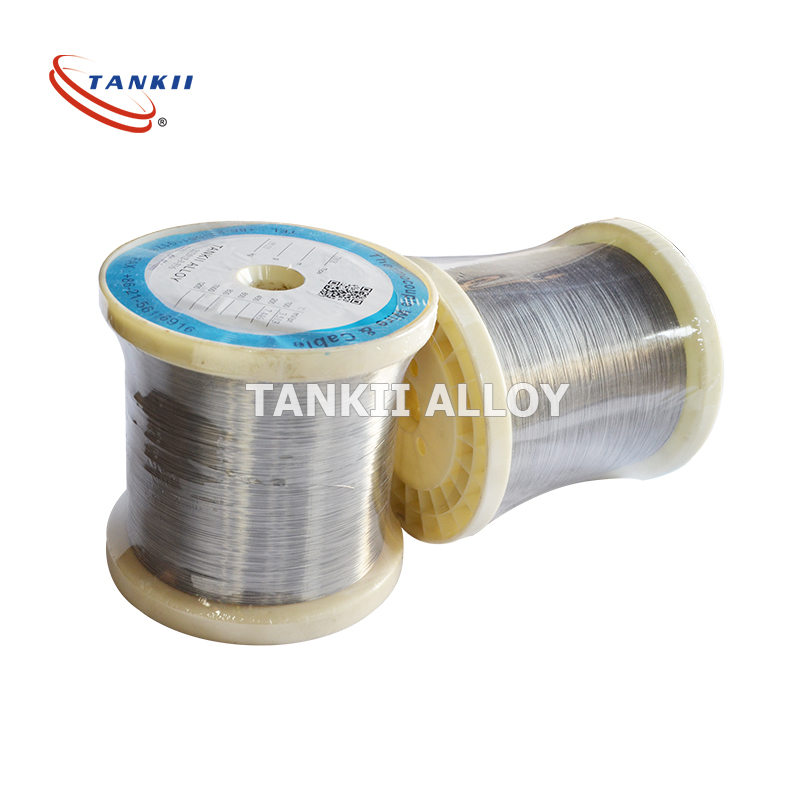

Radiator Inodzivirira Kupisa 0cr25al5 Alloy Wire Waya yeFecral inodzivirira Kupisa

Radiator Resistance Heating Waya Fecral 0cr25al5 Alloy Muruvara rweSilver Grey

1. Tsananguro Yakadzama

FeCrAl Alloy, 1Cr13Al4,0Cr23Al5, 0Cr25Al5, 0Cr20Al6RE, 0Cr21Al6Nb, 0Cr27Al7Mo2

FeCrAl Alloy imhando yeferritic iron-chromium-aluminium alloy (FeCrAl alloy) inoshandiswa mu arc neflame spray systems. Iyi alloy inogadzira machira akakora, anodzivirira kuoxidation uye ngura panguva yekupisa kwakanyanya.

Mashandisirwo kana Hunhu: Waya yekupfapfaidza ine simba rakanaka rekubatanidza. Zvidimbu zvakapfapfaidzwa zvechinhu ichi hazvichinji kana tembiricha yakakwira uye zvinoshandiswa sechikamu chekudzivirira kune mamwe ma alloys ese ekupfapfaidza.

0Cr25Al5

0Cr25Al5 isimbi yesimbi-chromium-aluminium (FeCrAl alloy) inoshandiswa mu arc neflame spray systems. Chiumbwa ichi chinoburitsa machira akakora, anodzivirira kuoxidation uye ngura panguva yekupisa kwakanyanya.

2. Zvimiro zveMichina

| Tembiricha Yebasa Rinoenderera Mberi Yakanyanya | 980ºC |

| Kusimba kwemuviri pa20ºC | 1.28 ohm mm2/m |

| Kuwanda kwevanhu | 7.4 g/cm3 |

| Kufambisa kwekupisa | 52.7 KJ/m@h@ºC |

| Kuwanda kweThermal Coefficient | 15.4×10-6/ºC |

| Nzvimbo Yokunyunguduka | 1450ºC |

| Simba reKusimba | 637~784 Mpa |

| Kureba | Zvishoma 12% |

| Kusiyana kweChikamu Kuderedza Mwero | 65~75% |

| Kukombama Kunowanzoitwa | Kashoma kashanu |

| Nguva Yebasa Rinoenderera Mberi | - |

| Kuoma | 200-260HB |

| Maumbirwo eMicrographic | Ferrite |

| Pfuma yeMagineti | Magineti |

3. Zvinhu Zvikuru

Kushanda kwakasimba; Kudzivirira oxidation; Kuramba ngura; Kukura kwakaderera; Kugadzikana kwekupisa kwakanyanya; Kugona kugadzira coil kwakanaka; Kurema kwepamusoro; Mamiriro akafanana uye akanaka epamusoro asina mavara

4. Zvigadzirwa nemasevhisi

1). Pasi: chitupa cheISO9001, uye chitupa cheSO14001;

2). Mabasa ekubhadhara faindi mushure mekutengesa;

3). Odha diki inogamuchirwa;

4). Hunhu hwakagadzikana kana tembiricha yakakwira;

5). Kutumirwa nekukurumidza.

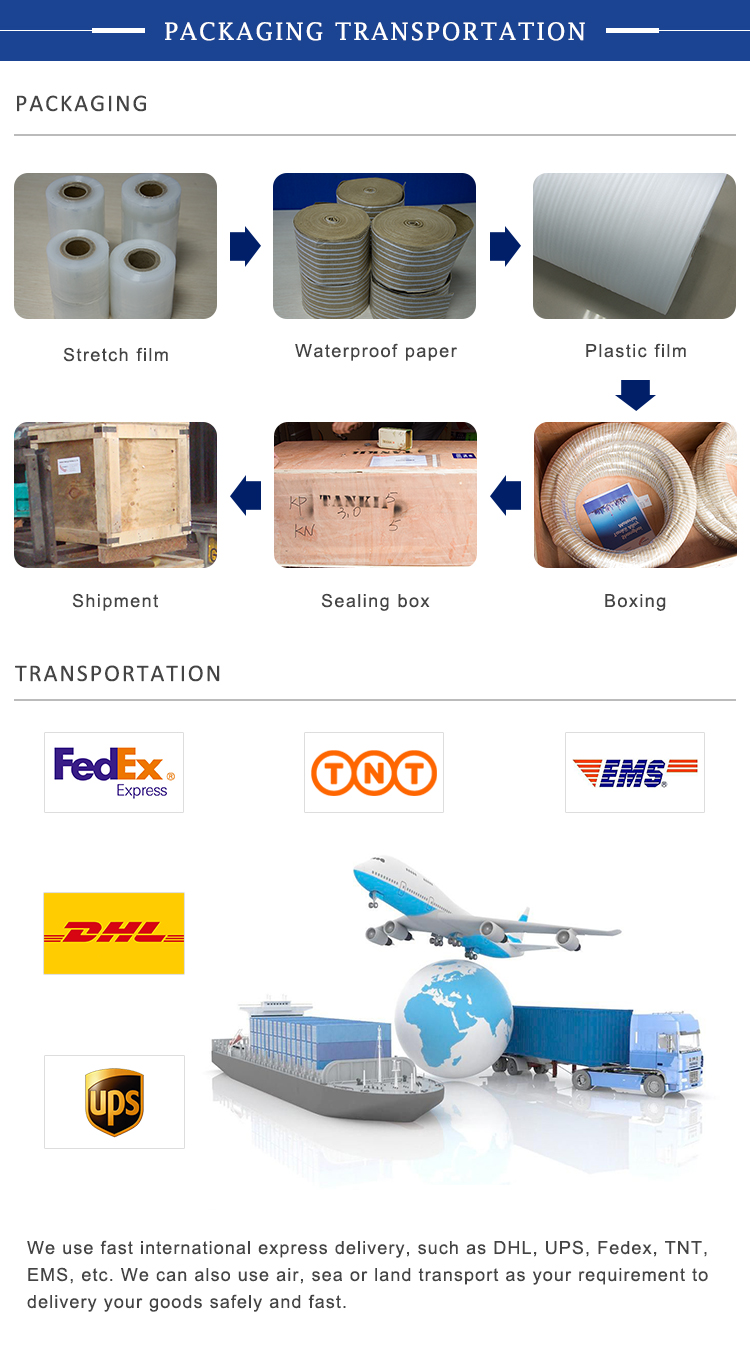

6). Chivharo, koiri, katoni, bhokisi remapuranga rine purasitiki kana rimwe bepa rekuputira zvinoenderana nezvinodiwa nemutengi.

5. Chinhu Chinokonzera Kupisa Kwemagetsi

| 20ºC | 100ºC | 200ºC | 300ºC | 400ºC | 500ºC | 600ºC | 700ºC | 800ºC | 900ºC | 1000ºC |

| 1 | 1.005 | 1.014 | 1.028 | 1.044 | 1.064 | 1.090 | 1.120 | 1.132 | 1.142 | 1.150 |

6. Kuumbwa kweMakemikoro

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Zvimwe | ||

| Max | |||||||||||

| 0.12 | 0.025 | 0.025 | 0.70 | 1.0 Yakanyanya | 13.0~15.0 | 0.60 yepamusoro | 4.5~6.0 | Bhari. | - | ||

Kana muchida, ndapota musazeza kutibata nesu.

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro