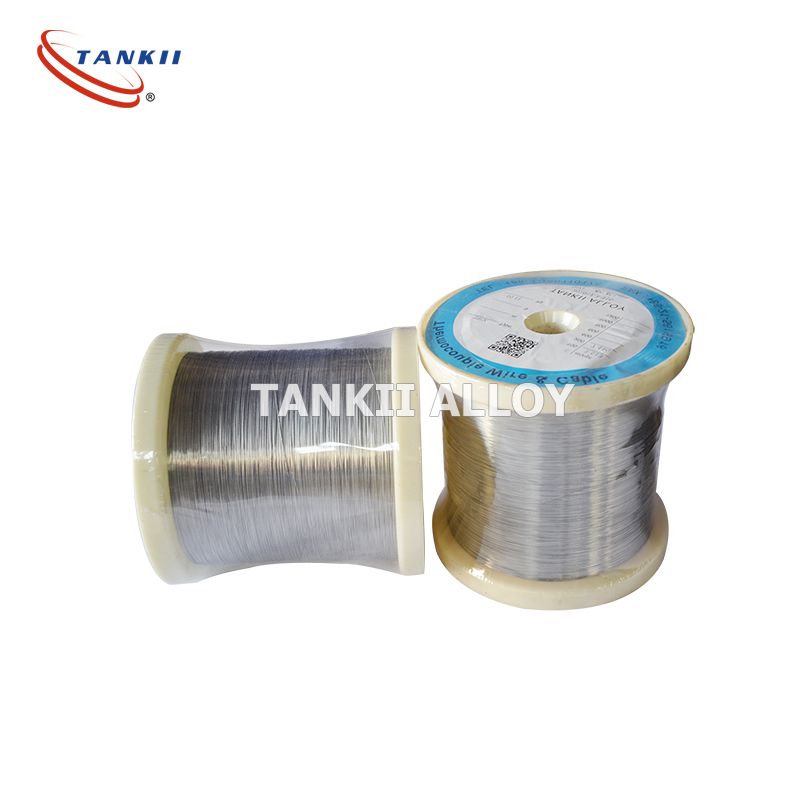

Waya yesimbi ye chrome alloy ye nickel Ni70Cr30

Waya yesimbi yechrome ine nickelNi70Cr30

Cr30Ni70 Nichrome Alloy Eletrothermal Coil Strip, Sable Resistance yeHeating Element,

NiCr70/30

Nickel chromium alloy ine iron resistance high resistivity, electrothermal high resistivity, pamusoro pemuviri zvakanaka. Pakupisa kwakanyanya uye simba rakawanda,

uye kushanda zvakanaka uye kugadziriswa kunogona kushandiswa zvakanyanya, simbi, magetsi, zvikamu zvemakanika uye zvemagetsi.

maindasitiri ekugadzira zvinhu zvinodzivirira kupisa.

Rudzi rweNiCr:Cr20Ni80,Cr15Ni60, Cr20Ni35, Cr20Ni30, Cr25Ni20 nezvimwewo. Bhandi remagetsi rakatsetseka, waya yemagetsi yemoto.

3. Saizi yechigadzirwa:

Ukobvu: 0.02—-4.0mm

Upamhi: 2.5—-250mm

Muyero: GB1234-95

Nzvimbo yakajeka uye yakatsetseka

Ni70Cr30

Zviri Mukati meKemikari, %

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Zvimwe |

| Max | |||||||||

| 0.08 | 0.02 | 0.015 | 0.60 | 0.75~1.60 | 28.0~31.0 | Bhari. | 0.50 yepamusoro | 1.0 Yakanyanya | - |

![]()

![]()

![]()

![]()

Zvivakwa zveMichina

| Kupisa Kwebasa Rinoenderera Mberi: Kusimba kwesimba (20ºC)/Ω·m::Kuwanda: Kufambisa kwekupisa: Kuwanda kweThermal Coefficient: Nzvimbo Yokunyunguduka: Kureba: Maumbirwo eMicrographic: Hunhu hweMagineti: | 1250ºC 1.18 +/-0.05 (Daya: <0.5mm) 1.20+/-0.05 (Dia: ≥0.50 mm) 8.1 g/cm3 45.2 KJ/m·h·ºC 17×10-6/ºC (20ºC~1000ºC) 1380ºC Zvishoma 20% Austenite isina magineti |

![]()

![]()

![]()

![]()

| Rudzi | Cr20Ni80 | Cr15Ni60 | Cr30Ni70 | Cr20Ni35 | Cr20Ni30 | |

| Kuumbwa kukuru kwemakemikari | Ni | Zorora | 55.0~61.0 | Zorora | 34.0~37.0 | 30.0~34.0 |

| Cr | 20.0~23.0 | 15.0~18.0 | 28.0~31.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | ≤1 | Zorora | ≤1 | Zorora | Zorora | |

| Kupisa Kwakanyanya (ºC) | 1200 | 1150 | 1250 | 1100 | 1100 | |

| Kudzivirira tembiricha yekugadzirisa chiyero. (CT) | 1.09±0.05 | 1.11±0.05 | 1.18±0.05 | 1.04±0.05 | 1.06±0.05 | |

| Nzvimbo yekunyunguduka (ºC) | 1400 | 1390 | 1380 | 1390 | 1390 | |

| Kudzivirira ρ20ºC(10-6Ω.m) | 800ºC | 1.008 | 1.078 | 1.028 | 1.188 | 1.173 |

| 1000ºC | 1.014 | 1.095 | 1.033 | 1.219 | 1.201 | |

| 1200ºC | 1.025 | 1.043 | ||||

| Kukosha kwehupenyu hwekukurumidza | Tem.(ºC) | 1175 | 1100 | 1200 | 1050 | 1050 |

| awa(h) | ≥110 | ≥100 | ≥110 | ≥100 | ≥100 | |

| Simba regiravhiti (g/cm3) | 8.40 | 8.2 | 8.1 | 7.90 | 7.90 | |

| Kureba (%) | ≥25 | ≥25 | ≥20 | ≥20 | ≥20 | |

| Kupisa (kj/mhºC) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Kupisa kwakananga (20ºC)j/g.ºC | 0.440 | 0.494 | 0.461 | 0.500 | 0.500 | |

| Wedzera simba (20~1000ºC)α*10-6ºC | 18.0 | 17.0 | 17.1 | 19.0 | 19.0 | |

| Simba rekusimba (kg/mm2) | >85 | >85 | >85 | >85 | >85 | |

| Kukotama kakawanda (F/R) | >12 | >12 | >12 | >12 | >12 | |

| Zvivako zvidiki | Austenitic | Austenitic | Austenitic | Austenitic | Austenitic | |

![]()

![]()

![]()

![]()

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro