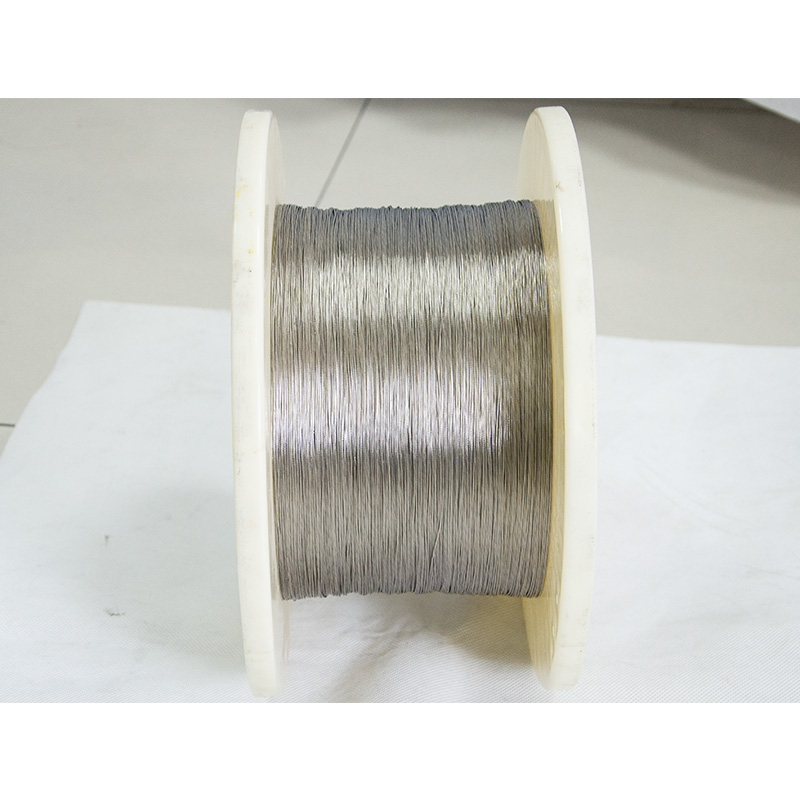

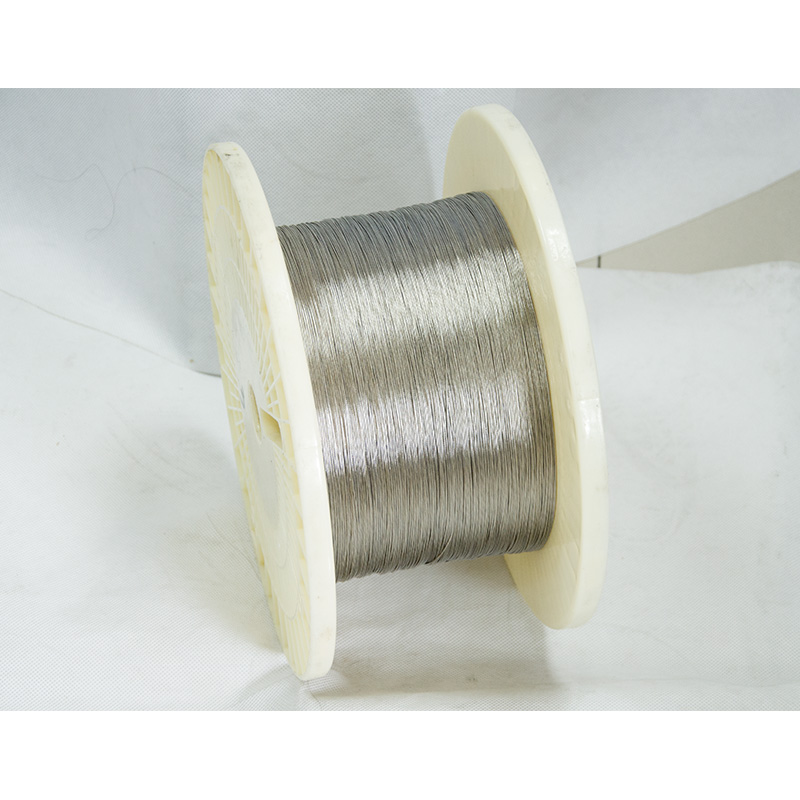

Waya yeNichrome yakasungirirwa Ni80 Waya yeKupisa yeNichrome Cr20ni80 Ni60Cr15 Ni35Cr20

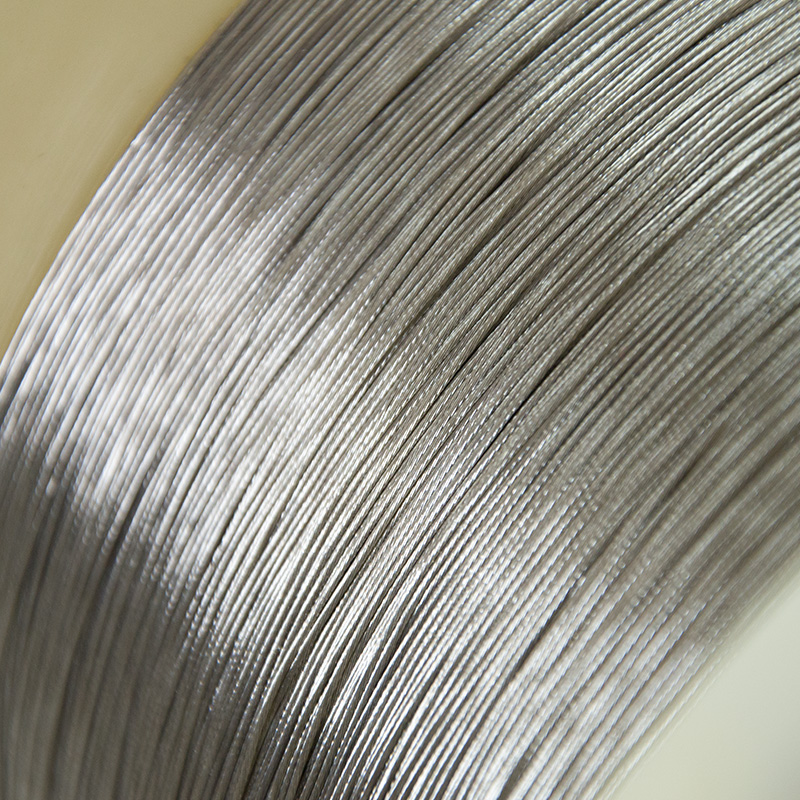

Waya inodzivisa kusimba inogadzirwa neNichrome alloys, dzakadai seNi80Cr20, Ni60Cr15, nezvimwewo. Inogona kugadzirwa netambo 7, tambo 19, kana tambo 37, kana zvimwe zvinhu.

Waya yekupisa ine simba rekudzivirira kupisa ine zvakanakira zvakawanda, zvakaita sekugona kuchinja, kugadzikana kwekupisa, hunhu hwemakanika, kugona kudzivirira kuvhunduka mukupisa uye kurwisa oxidization. Waya yeNichrome inoumba jira rekudzivirira rechromium oxide kana yapiswa kekutanga. Zvinhu zviri pasi pejira hazvizooxidization, zvichidzivirira waya kuti isaputsike kana kutsva. Nekuda kwesimba rayo rekudzivirira kupisa uye kuramba oxidation pakupisa kwakanyanya, inoshandiswa zvakanyanya muzvinhu zvinodziya, kupisa kwechoto chemagetsi uye maitiro ekurapa kupisa muindasitiri yemakemikari, yemakanika, yesimbi uye yekudzivirira,

| Kushanda \ zvinhu | Cr20Ni80 | |

| Kuumbwa | Ni | Zorora |

| Cr | 20.0~23.0 | |

| Fe | ≤1.0 | |

| Tembiricha yepamusoro ℃ | 1200 | |

| Nzvimbo yekunyunguduka ℃ | 1400 | |

| Kuwanda kwe g/cm3 | 8.4 | |

| Kuramba | 1.09±0.05 | |

| μΩ·m,20℃ | ||

| Kureba pakubvaruka | ≥20 | |

| Kupisa kwakananga | 0.44 | |

| J/g.℃ | ||

| Kufambisa kwekupisa | 60.3 | |

| KJ/mh℃ | ||

| Kuwedzera kwemiganhu yekoefficient | 18 | |

| a×10-6/℃ | ||

| (20~1000℃) | ||

| Maumbirwo ema micrographic | Austenite | |

| Hunhu hwemagineti | Isina magineti | |

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro