Kubudirira kukuru kweindasitiri yendege hakuparadzaniswi nekuvandudzwa uye kubudirira mune tekinoroji yezvinhu zvemuchadenga. Kureba kwepamusoro, kumhanya kwakanyanya uye kugona kufambisa ndege dzehondo zvinoda kuti zvinhu zvemuchadenga zvive nechokwadi chekuti ndege yacho ine simba rakakwana pamwe nekuomarara. Zvinhu zveinjini zvinofanirwa kusangana nezvinodiwa zvekudzivirira kupisa kwakanyanya, zvinhu zvinopisa zvakanyanya, zvinhu zvakagadzirwa neceramic ndizvo zvinhu zvikuru.

Simbi yakajairika inonyorova pamusoro pe300℃, zvichiita kuti isakodzere kushandiswa munzvimbo dzinopisa zvakanyanya. Mukutsvaga simba rakawanda rekushandura simba, tembiricha dzekushanda dzakakwira uye dzakakwira dzinodiwa mumunda wesimba reinjini yekupisa. Ma alloys ekupisa kwepamusoro akagadzirwa kuti ashande zvakanaka patembiricha dziri pamusoro pe600℃, uye tekinoroji iri kuramba ichichinja.

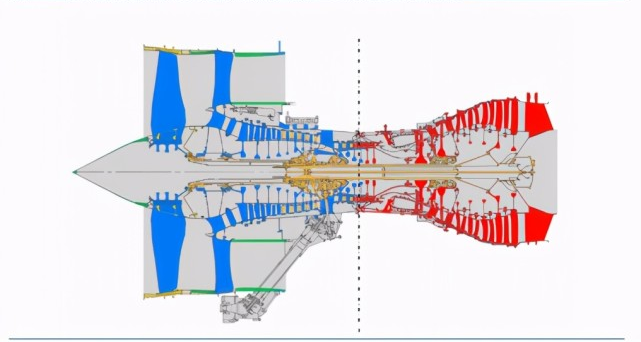

Ma alloys ekupisa kwakanyanya zvinhu zvakakosha zvemainjini emuchadenga, ayo akakamurwa kuita ma alloys ekupisa kwakanyanya akavakirwa pairon, akavakirwa pa nickel nezvinhu zvikuru zve alloy. Ma alloys ekupisa kwakanyanya ave achishandiswa mumainjini emuchadenga kubvira paakatanga, uye zvinhu zvakakosha mukugadzira mainjini emuchadenga. Kushanda kweinjini kunoenderana zvakanyanya nekushanda kwezvinhu zve alloy zvekupisa kwakanyanya. Muinjini dzemuchadenga dzemazuva ano, huwandu hwezvinhu zve alloy zvekupisa kwakanyanya hunoita 40-60 muzana yehuremu hwese hweinjini, uye hunonyanya kushandiswa kune zvikamu zvina zvikuru zvinopisa: makamuri ekupisa, ma guides, turbine blades uye turbine discs, uye pamusoro pezvo, inoshandiswa kune zvikamu zvakaita semagazini, rings, charge combustion chambers uye tail nozzles.

(Chikamu chitsvuku chedhayagiramu chinoratidza ma alloys anodziya zvakanyanya)

Ma alloys ekupisa kwepamusoro-soro akavakirwa pa nickel Kazhinji inoshanda pa600 ℃ pamusoro pemamiriro ezvinhu ekumanikidzwa, haina kungova nekudzivirira kwakanaka kwekuora nekuoxidation chete, uye ine simba rekupisa kwepamusoro-soro, simba rekukwira nekusimba, pamwe nekudzivirira kuneta. Inonyanya kushandiswa mumunda wendege nendege mumamiriro ekupisa kwepamusoro-soro, zvikamu zvechimiro, zvakaita semabhura einjini dzendege, madhisiki eturbine, makamuri ekupisa nezvimwewo. Ma alloys ekupisa kwepamusoro-soro akavakirwa pa nickel anogona kukamurwa kuita ma alloys ekupisa kwepamusoro-soro akakanganisika, ma alloys ekupisa kwepamusoro-soro uye ma alloys matsva ekupisa kwepamusoro-soro zvichienderana nemaitiro ekugadzira.

Kana tembiricha yekushanda kwe alloy isingapise kupisa yakakwira, zvinhu zvinosimbisa zviri mu alloy zvinowedzera kuoma, musanganiswa wacho wakaoma, zvichiita kuti mamwe ma alloy agone kushandiswa chete mumamiriro ekuumbwa, haagone kugadziriswa nekupisa. Uyezve, kuwedzera kwezvinhu zvinosanganisa alloy kunoita kuti ma alloy akavakirwa pa nickel arambe akasimba nekupatsanurwa kwakakomba kwezvikamu, zvichikonzera kusafanana kwehurongwa nemaitiro.Kushandiswa kwehupfu hwesimbi kugadzira alloys dzinopisa zvakanyanya kunogona kugadzirisa matambudziko ari pamusoro apa.Nekuda kwezvimedu zvidiki zveupfu, kukurumidza kutonhora kweupfu, kubvisa kupatsanurwa, kuvandudzwa kwekushanda kwekupisa, alloy yekutanga inogadzirwa mukupisa inoshanduka kuita kushanduka kwealloys dzekupisa zvakanyanya, simba rekugadzira uye hunhu hwekuneta zviri kuvandudzwa, alloy yekupisa kwepamusoro yeupfu yekugadzira alloys dzesimba rakakwirira yakagadzira nzira itsva.

Nguva yekutumira: Ndira-19-2024