Tinokugamuchirai kumawebhusaiti edu!

Muchitoro mune mhando yepamusoro ye ТБ2013/TM-2/108SP Bimetallic Strip yekutonga kweTemp

Tsananguro yeChigadzirwa

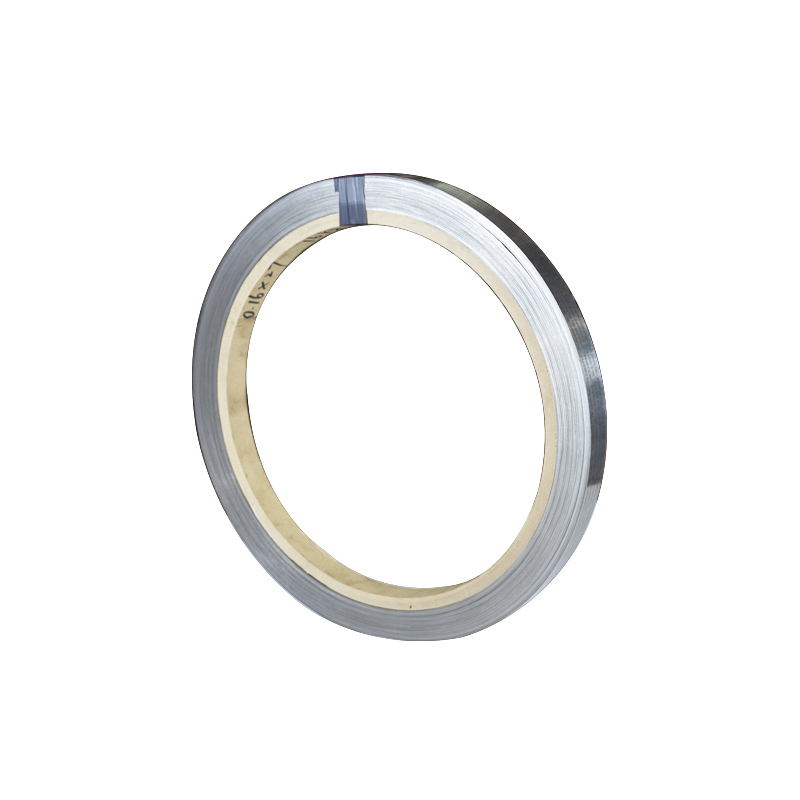

ТБ2013/TM-2/108SP Bimetallic Strip

Pfupiso yeChigadzirwa

ТБ2013/TM-2/108SP bimetallic strip, musanganiswa unoshanda zvakanaka wakagadzirwa uye wakagadzirwa neTankii Alloy Material, imhando yepamusoro yakagadzirirwa thermal actuation scenarios pakati nepakati kusvika pakakwirira. Yakagadzirwa ne alloys mbiri dzakasiyana dzine thermal expansion coefficients dzakanyatsodzorwa—dzakabatanidzwa kuburikidza nehunyanzvi hweHuona hwe hot-rolling diffusion technology—mutsetse uyu unobatanidza zvakanakira zvitatu zvikuru: static tembiricha response, mechanical fatigue resistance yakanaka, uye broad environment adjustment. Kusiyana ne generic bimetallic strips, ТБ2013/TM-2/108SP grade yakagadzirirwa kuenzana thermal sensitivity uye structure strength, zvichiita kuti ive yakakodzera ma industrial thermostats, motor overheat protectors, uye precision tembiricha compensation components in operating environments (semuenzaniso, high humidity, vibration).

Mazita Akajairwa & Kuumbwa Kwakakosha

- Giredhi reChigadzirwa: ТБ2013/TM-2/108SP

- Maumbirwo eComposite: Kazhinji ine "high-expansion layer" uye "low-expansion layer"; simba rekubatanidza pakati pechiso ≥140 MPa

- Mitemo Inotevedzera: Inotevedzera GOST 28561-90 (muyero wekuRussia wezvimedu zve bimetallic) uye IEC 60694 yezvikamu zvekudzora kupisa; inoenderana nezvinodiwa neEU RoHS

- Mugadziri: Tankii Alloy Material, ine chitupa cheISO 9001 neISO 14001, ine hunyanzvi hwekugadzira alloy mukati meimba uye kugona kubatana kwecomposite kuti ienderane nezvinodiwa zvegiredhi repamusoro.

Mabhenefiti Akakosha (zvichienzaniswa neGeneric Bimetallic Strips)

ТБ2013/TM-2/108SP inonyatso shanda zvakanaka pakushandisa kwayo, ichigadzirisa matambudziko mukushandiswa kwemaindasitiri nenzvimbo dzakaoma:

- Kuchinjika pakupisa kwakakura: Inoshanda zvakanaka mu -50℃ kusvika 250℃ (kushandiswa nguva dzose), ine simba rekudzivirira kwenguva pfupi kusvika 300℃—inodarika tambo dze bimetallic dzakajairwa (dzinogumira ku ≤200℃) uye yakakodzera kumaindasitiri anodziya zvakanyanya (semuenzaniso, ma sensor einjini).

- Kupisa Kushoma: Kukanganisa kweHysteresis ≤3℃ (pakati penzvimbo dzekupisa nekutonhodza) pa150℃—zvinokosha pakudzora tembiricha nemazvo (semuenzaniso, mathermostat eovheni yeindasitiri) apo kudzokororwa kwekudzima/kudzima kunoda mwero wakaenzana.

- Kuramba Kuneta Kwakasimba: Inotsungirira ≥15,000 thermal cycles (-50℃ kusvika 250℃) isina interfacial delamination kana performance decay—3 × hupenyu hwebasa hwakareba kupfuura strips dzisina giredhi rakaderera, zvichideredza mari yekugadzirisa michina inoshanda kwenguva refu (semuenzaniso, masisitimu eHVAC).

- Kuramba Kudedera & Kuora: Simba rekutenderera rinotenderera ≥460 MPa rinoita kuti chimiro chigadzikane pasi pekudedera (rinoenderana neIEC 60068-2-6 vibration tests); zinc-plating inosarudzwa inopa kudzivirira kupfapfaidza munyu kwemaawa makumi mapfumbamwe nematanhatu (ASTM B117) kune nzvimbo dzine hunyoro kana dzinoparadza (semuenzaniso, midziyo yemugungwa).

- Kunyatsoenderana Nemadimikira: Inowanikwa muukobvu hwakafanana (0.15mm–0.8mm) uye upamhi (10mm–200mm) ine kutsungirira ≤±0.005mm (ukobvu) uye ≤±0.1mm (upamhi)—ichibvumira otomatiki stamping uye kubatanidzwa muzvikamu zvemaindasitiri zvakajairika.

Magadzirirwo ehunyanzvi

| Hunhu | Kukosha (Kwakajairika) |

|---|---|

| Ukobvu Range | 0.15mm – 0.8mm (yakagadziriswa kusvika 1.2mm) |

| Upamhi hweRange | 10mm – 200mm (hupamhi hwakajairika: 15mm, 20mm, 27mm) |

| Kureba paRoll | 50m – 300m (yakachekwa kusvika pakureba iripo: ≥100mm) |

| Chiyero chekuwedzera kwemafuta (Chikamu chepamusoro/chakaderera) | ~4:1 |

| Kushanda Tembiricha Range | -50℃ kusvika 250℃ (inoenderera mberi); Nguva pfupi: kusvika 300℃ (≤awa imwe) |

| Kutsauka kweTembiricha yeActivation | ±2℃ (padanho rekushanda rakayerwa, 80℃–200℃) |

| Simba reKucheka reInterfacial | ≥140 MPa |

| Simba Rekusimba (Kuchinjika) | ≥460 MPa |

| Kureba (25℃) | ≥14% |

| Kuramba (25℃) | 0.20 – 0.35 Ω·mm²/m |

| Kuoma Kwepamusoro (Ra) | ≤0.8μm (kupedzisa kwemugayo); ≤0.4μm (kupedzisa kwakakweshwa, sarudzo) |

Zvimiro zveChigadzirwa

| Chinhu | Tsanangudzo |

|---|---|

| Kupedzisa Kwepamusoro | Kupedzisa kwemugayo (isina oxide) kana kuti zinc-plated/nickel-plated (yekudzivirira ngura zvakanyanya) |

| Kufara | ≤0.1mm/m (zvakakosha pakuchinja kwakafanana kwekupisa uye kunyatso simbisa) |

| Kugona kuchinjika | Inoenderana neCNC stamping, laser cutting, uye bend; hapana interfacial cracking panguva yekugadzirisa (kukombama kwe radius ≥3× ukobvu) |

| Hunhu hwekubatana | 100% interfacial bonding (hapana voids >0.1mm², yakasimbiswa kuburikidza ne X-ray inspection uye ultrasound testing) |

| Kurongedza | Yakavharirwa mupurasitiki mumabhegi ealuminium foil asinganyoroveswe nemvura ine desiccant; mapuranga anoputirwa (emarolls) kana makatoni asingakotami (emapepa akachekwa) kudzivirira kuputsika kwemvura |

| Kugadzirisa | Kugadziriswa kwekupisa kwemagetsi (60℃–220℃), kufukidza pamusoro, maumbirwo akatoiswa stampu (pamafaira eCAD emutengi), uye ukobvu/upamhi husina kuenzana |

Maitiro Akajairika

- Kudzora Kupisa Kwemaindasitiri: Mathermostat emaovheni emaindasitiri, mabhoyira, uye masisitimu eHVAC; zvinodzora tembiricha zvemichina yekuumba mapurasitiki (inoshanda pa120℃–200℃).

- Dziviriro yekupisa zvakanyanya: Zvinopwanya macircuit ekupisa emota dzemagetsi (semuenzaniso, mapombi eindasitiri, macompressor) uye mapower transformer—zvinodzivirira kupisa nekubvisa macircuit pa150℃–250℃.

- Mota & Marine: Zvinonzwa tembiricha uye zvinodzivirira zvikamu zveinjini (mota) uye midziyo yemugungwa (inodzivirira kudedera uye ngura yemvura ine munyu).

- Zvishandiso Zvekunyatsoongorora: Zvinhu zvinotsiva tembiricha ye pressure gauges, flow meter, uye MEMS sensors—zvinogadzirisa zvikanganiso zvekuwedzera kwekupisa kuti zvirambe zvakarurama pakuyera.

- Midziyo Yemumba Neyemabhizinesi: Zvidziviriro zvinopisa zvakanyanya zvezvidziyo zvemagetsi zvemvura, zvinotonhodza mhepo, uye mafiriji emabhizimisi (kushanda kwakagadzikana munzvimbo dzine hunyoro hwakawanda).

Tankii Alloy Material inoshandisa kudzora kwakasimba kwemhando ye ТБ2013/TM-2/108SP bimetallic strips: batch yega yega inoongororwa interfacial shear, 1000-cycle thermal stability testing, dimensional inspection (laser micrometry), uye actuation temperature calibration. Samples dzemahara (100mm×20mm) uye mishumo yakadzama yekushanda (kusanganisira thermal curvature vs. temperature curves) zviripo kana zvakumbirwa. Chikwata chedu chehunyanzvi chinopa rutsigiro rwakagadzirirwa iwe—senge alloy layer optimization yekupisa kwakanangana nekushanda uye gwara rekuenderana nemaitiro ekugadzira maindasitiri—kuona kuti strip iyi inosangana nezvinodiwa chaizvo zvemaindasitiri eEurasia nepasi rose.

Nyora meseji yako pano woitumira kwatiri

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro