Tinokugamuchirai kumawebhusaiti edu!

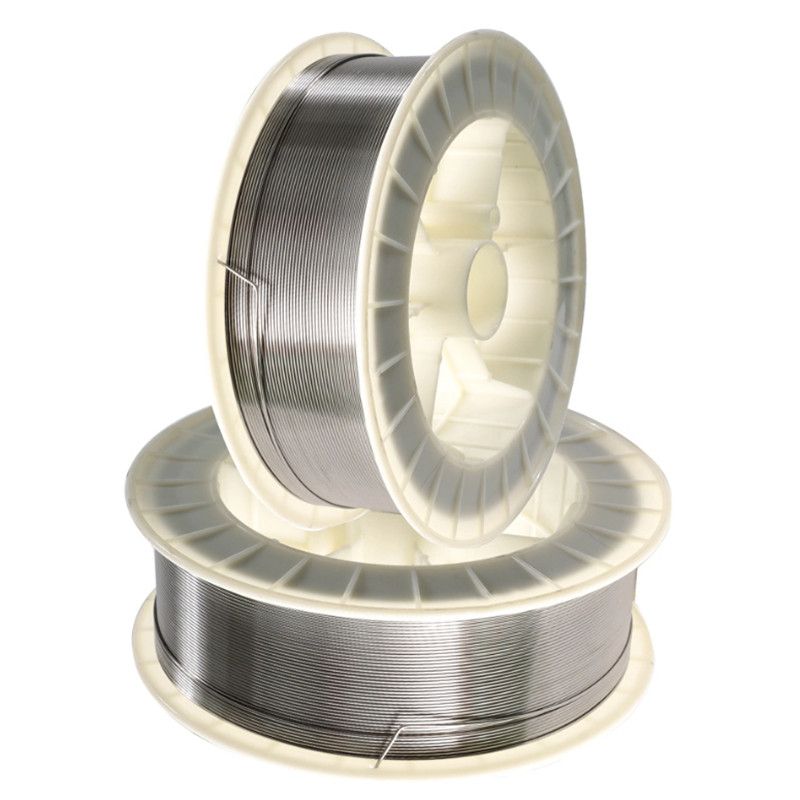

Kuramba Kushanda Zvakanaka kweOxidation 0.05MM NiCr 60 15 yePotentiometer Resistors

NiCr 60 15 (2.4867) inoshandiswa pakugadzira zvinhu zvinodziya zvemagetsi mumidziyo yemumba. Zvinhu zvakajairika zvinoshandiswa mumidziyo yesimbi ine sheathed tubular, semuenzaniso, mahot plates, magrill, maoven etoaster uye maheaters ekuchengetera zvinhu. Ma alloys 6015 anoshandiswawo pakugadzira ma coils akasungirirwa muair heaters muma clothe dryer, ma fan heaters, uye ma hand dryer.

- zvinodzivirira zvakanyanya uye zvinodzivirira simba remagetsi.

- zvinhu zvinodziya zvemagetsi (kushandiswa kumba uye mumaindasitiri).

- maovheni emaindasitiri anosvika 1100°C.

| Giredhi | Ni80Cr20 | Ni70Cr30 | Ni60Cr23 | Ni60Cr15 | Ni35Cr20 | Karma | Evanohm | |

| Musanganiswa wezita% | Ni | Bhari | Bhari | 58.0-63.0 | 55.0-61.0 | 34.0-37.0 | Bhari | Bhari |

| Cr | 20.0-23.0 | 28.0-31.0 | 21.0-25.0 | 15.0-18.0 | 18.0-21.0 | 19.0-21.5 | 19.0-21.5 | |

| Fe | ≦1.0 | ≦1.0 | Bhari | Bhari | Bhari | 2.0-3.0 | – | |

| Al1.0-1.7 Ti 0.3-0.5 | Al2.7-3.2 Mn0.5-1.5 | Al2.7-3.2 Cu2.0-3.0 Mn0.5-1.5 | ||||||

| Tembiricha yepamusoro yekushanda (°C) | 1200 | 1250 | 1150 | 1150 | 1100 | 300 | 400 | |

| Kugadzikana kwesimba (Ω/cmf, 20℃) | 1.09 | 1.18 | 1.21 | 1.11 | 1.04 | 1.33 | 1.33 | |

| Kusimba kwemuviri (uΩ/m, 60°F) | 655 | 704 | 727 | 668 | 626 | 800 | 800 | |

| Kuwanda (g/cm³) | 8.4 | 8.1 | 8.4 | 8.2 | 7.9 | 8.1 | 8.1 | |

| Kufambisa kwekupisa (KJ/m·h·℃) | 60.3 | 45.2 | 45.2 | 45.2 | 43.8 | 46.0 | 46.0 | |

| Kuwedzerwa kweCoefficient yeKuwedzera kweLinear (×10¯)6/℃)20-1000℃) | 18.0 | 17.0 | 17.0 | 17.0 | 19.0 | - | - | |

| Nzvimbo Yekunyunguduka (℃) | 1400 | 1380 | 1370 | 1390 | 1390 | 1400 | 1400 | |

| Kuoma (Hv) | 180 | 185 | 185 | 180 | 180 | 180 | 180 | |

| Simba reKusimba (N/mm)2 ) | 750 | 875 | 800 | 750 | 750 | 780 | 780 | |

| Kureba (%) | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | 10-20 | 10-20 | |

| Maumbirwo eMicrographic | austenite | austenite | austenite | austenite | austenite | austenite | austenite | |

| Zvivakwa zveMagineti | Kwete | Kwete | Kwete | Zvishoma | Kwete | Kwete | Kwete | |

| Hupenyu Hwakakurumidza (h/℃) | ≥81/1200 | ≥50/1250 | ≥81/1200 | ≥81/1200 | ≥81/1200 | - | - | |

Nyora meseji yako pano woitumira kwatiri

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro