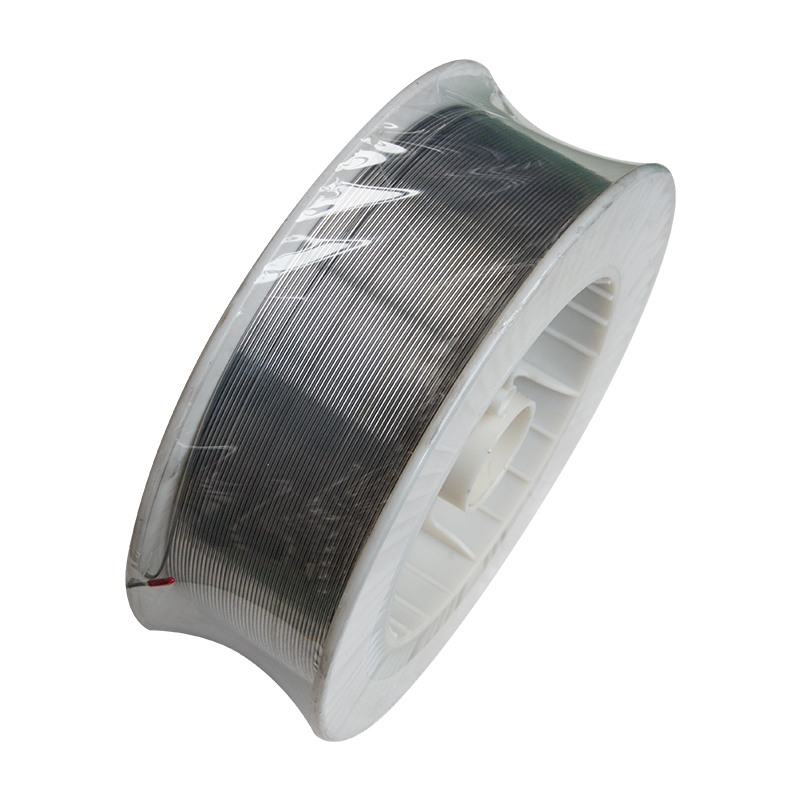

Waya Yekushongedza Yemahara Yesimbi Yakadzivirirwa neArc yemhangura Er70s-6, Sg2

Nhanganyaya ye waya yekuwedera isina Copper:

Mushure mekushandisa tekinoroji inoshanda ye nanometer, pamusoro pewaya yekuwelda isina mhangura hapana chikero chemhangura uye pane kugadzikana kwakanyanya pakudyisa waya, izvo zvinonyanya kukodzera pakuwelda nerobhoti otomatiki. Arc inoonekwa nekugadzikana kwakasimba, kusapararira kwakawanda, kusashanda zvakanaka kwemuromo wekubata uye kudzika kukuru kwekuiswa kwewelding. Nzvimbo yekushanda yevashandi inovandudzwa zvikuru nekuti waya yekuwelda isina mhangura haina utsi hwemhangura. Nekuda kwekuvandudzwa kwenzira yekurapa pamusoro mutsva, waya yekuwelda isina mhangura inodarika waya yakakweshwa mukudzivirira ngura, ine zvinhu zvinotevera.

1. mutsetse wakasimba kwazvo.

2. Zvidimbu zvishoma zvinopfapfaidza

3. Hunhu hwepamusoro hwekudyisa waya.

4. Kudzora zvakanaka tambo

5.Inodzivirira ngura zvakanaka pamusoro pewaya yekuwelding.

6.Hapana chizvarwa cheutsi hwemhangura.

7. Kusanyanya kupera kwemuromo wekubata magetsi.

Zvekungwaririra:

1. Maparamita ekugadzirisa welding anokanganisa hunhu hwemakanika esimbi inoweld, uye mushandisi anofanira kuita zvinodiwa pakuweld uye kusarudza zvine musoro maparamita ekugadzirisa welding.

2. Ngura, hunyoro, mafuta, guruva nezvimwe tsvina zviri munzvimbo yekunamira zvinofanirwa kubviswa zvakasimba usati wanamira.

Magadzirirwo:Dhayamita: 0.8mm, 0.9mm, 1.0mm, 1.2mm, 1.4mm, 1.6mm, 2.0mm

Saizi yekurongedza: 15kg/20 kg pa spool imwe neimwe.

Kuumbwa kwemakemikari kwakajairika kwewaya yekuwedera(%)

== ...

| Chinhu | C | Mn | Si | S | P | Ni | Cr | Mo | V | Cu |

| Chinodiwa | 0.06-0.15 | 1.40-1.85 | 0.80-1.15 | ≤0.025 | ≤0.025 | ≤0.15 | ≤0.15 | ≤0.15 | ≤0.03 | ≤0.50 |

| Mhedzisiro yeAVG chaiyo | 0.08 | 1.45 | 0.85 | 0.007 | 0.013 | 0.018 | 0.034 | 0.06 | 0.012 | 0.28 |

Hunhu hweMechanical hwesimbi yakachengetwa

== ...

| Chinhu Chekuyedza | Simba rekusimba Rm(Mpa) | Simba rekupa Rm(Mpa) | Kureba A(%) | Bvunzo reBump remuenzaniso weV | |

| Tembiricha Yekuyedza (ºC) | Kukosha Kwemhedzisiro (J) | ||||

| Zvinodiwa | ≥500 | ≥420 | ≥22 | -30 | ≥27 |

| Mhedzisiro yeAVG chaiyo | 589 | 490 | 26 | -30 | 79 |

Saizi uye huwandu hwazvino hunokurudzirwa.

==================================================

| Dhayamita | 0.8mm | 0.9mm | 1.0mm | 1.2mm | 1.6mm | 1.6mm |

| Maampisi | 50-140 | 50-200 | 50-220 | 80-350 | 120-450 | 120-300 |

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro