FeCrAl FeCr23Al5 A1 APM AF D Waya yemagetsi inodzivirira kupisa

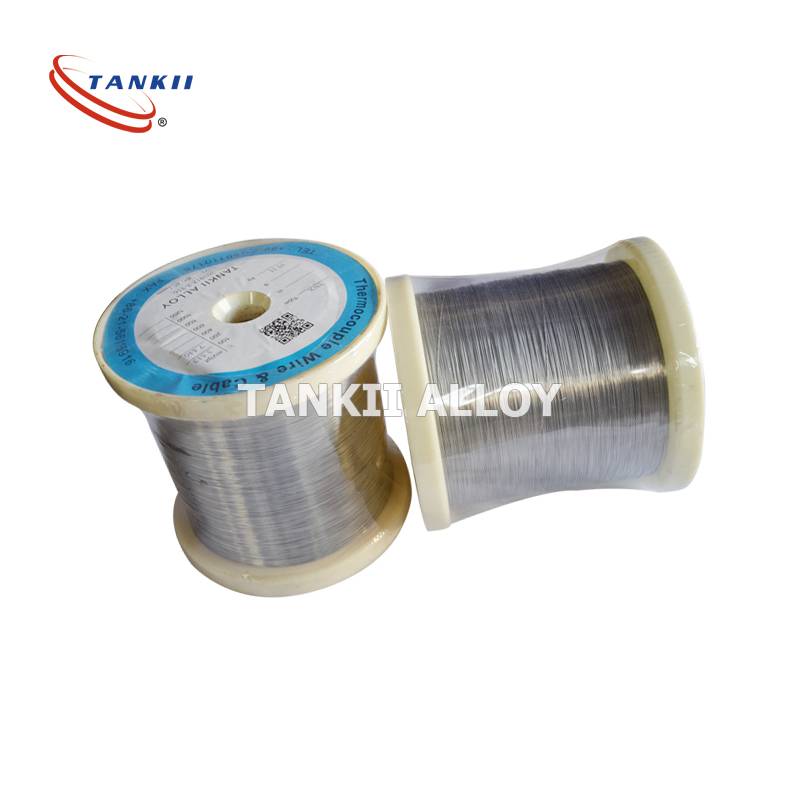

Waya yemagetsi inodzivirira kupisa yeFeCrAl A1 APM AF D Alloy

Nezve Resistance Heating Wire:

Isu tiri vagadziri vepamusoro-soro vezvishandiso zvekupisa zvinodzivirira kupisa muChina, tichinyanya kugadzira waya dzeFerro-Chrome (Fe-Cr-AL), waya dzeNickel-Chrome (Nichrome), waya dzeCopper Nickel (Constantan), waya dzesimbi dzisina ngura nezvimwe zvigadzirwa zvine chekuita nazvo zvakagadzirwa kuti zvienderane nezvinodiwa nevatengi.

Ruzivo rwehukuru

| Zita rechigadzirwa | Saizi yehukuru |

| Waya yekudhirowa inotonhora | Dhayamita 0.03-7.5mm |

| Tsvimbo yewaya inopetwa inopisa | Dhayamita 8.0-12mm |

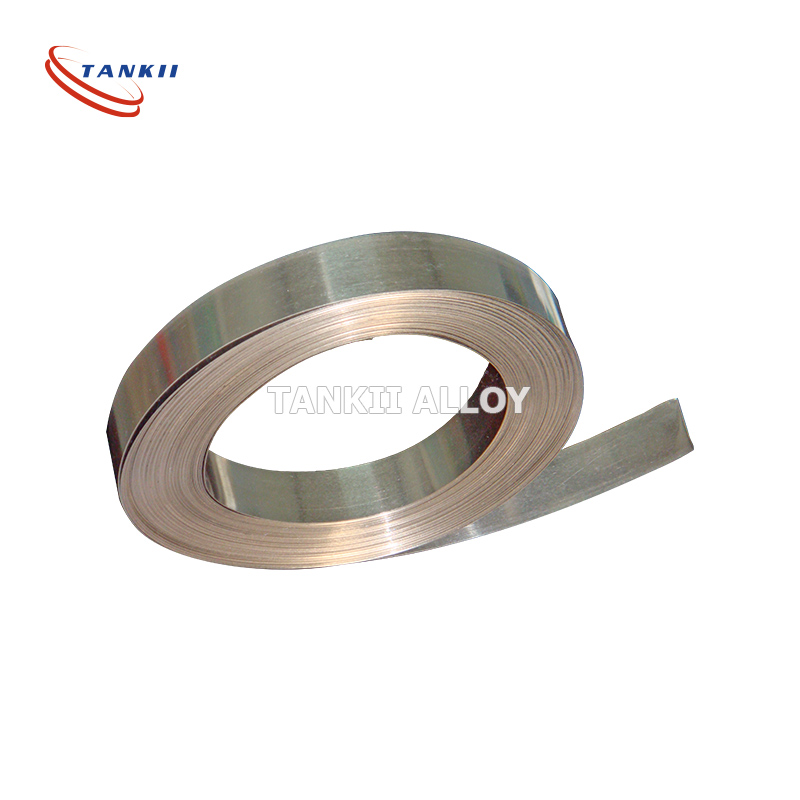

| Ribhoni | Ukobvu 0.05-0.35mm |

| Upamhi 0.5.0-3.5mm | |

| Chidimbu chakamonerwa chinotonhora | Ukobvu 0.5-2.5mm |

| Upamhi 5.0-40mm | |

| tambo yakamonerwa inopisa | Ukobvu 4-6mm |

| Upamhi 15-40mm |

parameters huru:

| parameters huru | APMTM | FeCrAl | ||

| A-1 | AF | D | ||

| Tembiricha yekushanda inoenderera mberi yepamusoro-soro | 1425 | 1400 | 1300 | 1300 |

| Muumbirwo wemakemikari wezita,% Cr | 22 | 22 | 22 | 22 |

| AI | 5.8 | 5.8 | 5.3 | 4.8 |

| Fe | zvinoshandiswa | zvinoshandiswa | zvinoshandiswa | zvinoshandiswa |

| Ni | - | - | - | - |

| Kudzivirira kwe 20ºC, Ωmm-2mm-1 | 1.45 | 1.45 | 1.39 | 1.35 |

| kuwanda, g/cm3 | 7.1 | 7.1 | 7.15 | 7.25 |

| Chiyero chekuwedzera kwekupisa K-1 20-750ºC | 14×10-6 | 14×10-6 | 14×10-6 | 14×10-6 |

| 20-1000ºC | 15×10-6 | 15×10-6 | 15×10-6 | 15×10-6 |

| Kufambisa kwekupisa 20ºC,Wm-1K-1 | 13 | 13 | 13 | 13 |

| Kugona kupisa kwakananga 20ºC, KJkg-1K-1 | 0.46 | 0.46 | 0.46 | 0.46 |

| Nzvimbo yekunyungudukaºC | 1500 | 1500 | 1500 | 1500 |

| Zvichida hunhu hwemakanika | ||||

| Simba rekusimba, N mm-2 | 680 | 680 | 680 | 650 |

| Simba regoho, N mm-2 | 470 | 475 | 475 | 450 |

| Kuomarara, Hv | 230 | 230 | 230 | 230 |

| Kupwanya kureba,% | 20 | 18 | 18 | 18 |

| 900ºCTSimba rehutete, N mm-2 | 40 | 34 | 37 | 34 |

| Simba rekupinda 800ºC | 11 | 6 | 8 | 6 |

| 1000ºC | 3.4 | 1 | 1.5 | 1 |

| Magineti | magineti (Mutembiricha 600ºC) | |||

| Kubuda kwemhepo, mamiriro ekuoxidation | 0.7 | 0.7 | 0.7 | 0.7 |

Tsanangudzo:

| Rudzi rwechiwanikwa | Dhayamita | Kuramba | Kusimba | Kureba (%) | Kukotama | Max.Continuous | Hupenyu hwekushanda |

| (mm) | (μΩm)(20°C) | Simba | Nguva | Basa | (maawa) | ||

| (N/mm²) | Tembiricha(°C) | ||||||

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

Zvakanakira:

Nickelchromium alloy ine simba rakasimba uye rakagadzikana, inodzivirira ngura, inodzivirira oxidation pamusoro, ine simba rakanaka kana tembiricha yakakwira uye simba rekudengenyeka kwenyika, ine ductility yakanaka, inoshanda zvakanaka uye inogona kusvetwa.

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro