Waya yeOvheni yeMagetsi Waya yeChitofu cheMagetsi yeMaindasitiri Furnace Inodzivirira Kupisa

Waya yeOvheni yeMagetsi Waya yeChitofu cheMagetsi yeMaindasitiri Waya yeChitofu cheMagetsi Inodzivirira Kupisa

Ruzivo Rwakawanda

Waya yemagetsi inogadzirwa neovheni imhando yewaya yemagetsi inopikisa simba rayo. Waya iyi inodzivirira kufamba kwemagetsi, uye inoshandura simba remagetsi kuita kupisa.

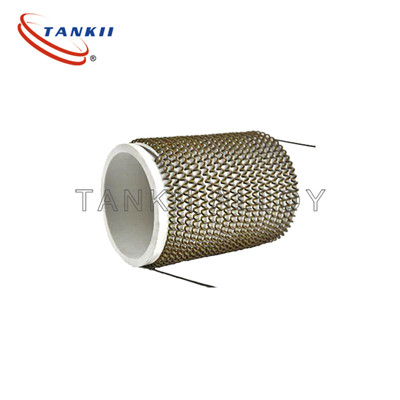

Kushandiswa kwewaya dzinodzivirira kunosanganisira zvinodzivirira, zvinhu zvinodziya, zvinodziya zvemagetsi, maovheni emagetsi, matoaster, nezvimwe zvakawanda.

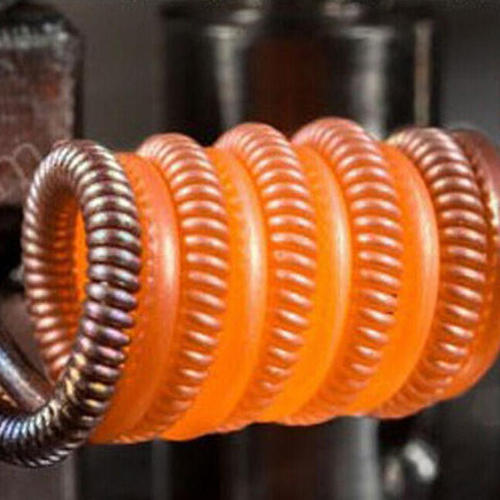

Nichrome, iyo isiri magnetic alloy ye nickel ne chromium, inowanzoshandiswa kugadzira waya ye resistance nekuti ine resistivity yakanyanya uye inodzivirira oxidation pakupisa kwakanyanya. Kana ikashandiswa se heating element, waya ye resistance inowanzo sungirirwa kuita coils. Dambudziko rimwe pakushandisa Electric Oven Wire nderekuti common electrical solder haibatire pairi, saka kubatanidza kune magetsi kunofanirwa kuitwa uchishandisa dzimwe nzira dzakadai se crimp connectors kana screw terminals.

FeCrAl, mhuri yesimbi-chromium-aluminium alloys inoshandiswa mumhando dzakasiyana-siyana dzekudzivirira uye kushandiswa pakupisa kwakanyanya, inoshandiswawo muchimiro chewaya dzinodzivirira.

Hunhu & Zvimiro

| Kusarudzwa kwezvinhu | Rimwe Zita | Kuumbwa Kwemakemikari Asina Kunaka | |||||

| Ni | Cr | Fe | Nb | Al | Zorora | ||

| Nickel Chrome | |||||||

| Cr20Ni80 | NiCr8020 | 80.0 | 20.0 | ||||

| Cr15Ni60 | NiCr6015 | 60.0 | 15.0 | 20.0 | |||

| Cr20Ni35 | NiCr3520 | 35.0 | 20.0 | 45.0 | |||

| Cr20Ni30 | NiCr3020 | 30.0 | 20.0 | 50.0 | |||

| Aruminiyamu yesimbi yeChrome | |||||||

| OCr25Al5 | CrAl25-5 | 23.0 | 71.0 | 6.0 | |||

| OCr20Al5 | CrAl20-5 | 20.0 | 75.0 | 5.0 | |||

| OCr27Al7Mo2 | 27.0 | 65.0 | 0.5 | 7.0 | 0.5 | ||

| OCr21Al6Nb | 21.0 | 72.0 | 0.5 | 6.0 | 0.5 | ||

| Kusarudzwa kwezvinhu | Kuramba kwe µOhms/cm | Kuwanda kweG/cm3 | Kuwedzerwa Kwemutsetse Kwekoefficient | Kufambisa kwekupisa W/mK | |

| µm/m.°C | Kupisa°C | ||||

| Nickel Chrome | |||||

| Cr20Ni80 | 108.0 | 8.4 | 17.5 | 20-1000 | 15.0 |

| Cr15Ni60 | 112.0 | 8.2 | 17.5 | 20-1000 | 13.3 |

| Cr20Ni35 | 105.0 | 8.0 | 18.0 | 20-1000 | 13.0 |

| Aruminiyamu yesimbi yeChrome | |||||

| OCr25Al5 | 145.0 | 7.1 | 15.1 | 20-1000 | 16.0 |

| OCr20Al5 | 135.0 | 7.3 | 14.0 | 20-1000 | 16.5 |

Mashandisirwo Anokurudzirwa

| Kusarudzwa kwezvinhu | Zvivakwa zveSevhisi | Mashandisirwo |

| Nickel Chrome | ||

| Cr20Ni80 | Ine zvinhu zvinogara kwenguva refu zvinoita kuti ive yakakodzera kushandiswa kana paine kuchinja-chinja kwekushisa uye kuchinja-chinja kwekupisa. Inogona kushandiswa pakupisa kunosvika 1150 °C. | Zvidziviriro zvekudzora, mavira ekupisa kwakanyanya, simbi dzinosungirirwa. |

| Cr15Ni60 | Chidimbu cheNi/Cr chine Iron yakaringana, chine simba rekuwedzera rinogara kwenguva refu. Chakakodzera kushandiswa kusvika 1100 °C, asi simba rayo rekudzivirira rinoita kuti chisanyanya kuoma kupfuura 80/20. | Zvidziyo zvemagetsi, zvinodzivirira simba guru, mavira emagetsi. |

| Cr20Ni35 | Iron inonyanya kuenzana. Yakakodzera kushandiswa nguva dzose kusvika 1050°C, mumaovheni ane mhepo inogona kukonzera ngura yakaoma yezvinhu zvine nickel yakawanda. | Zvidziyo zvemagetsi, maovheni emagetsi (ane mhepo). |

| Aruminiyamu yesimbi yeChrome | ||

| OCr25Al5 | Inogona kushandiswa mumamiriro ekushanda anosvika 1350°C, kunyange zvazvo inogona kupwanyika. | Zvinhu zvinopisa zvemaovheni anodziya zvakanyanya uye zvinopisa zvinopenya. |

| OCr20Al5 | Chiumbwa chine ferromagnetic chinogona kushandiswa pakupisa kusvika 1300°C. Chinofanira kushandiswa munzvimbo dzakaoma kudzivirira ngura. Chinogona kusviba kana kupisa kwakakwira. | Zvinhu zvinopisa zvemaovheni anodziya zvakanyanya uye zvinopisa zvinopenya. |

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro