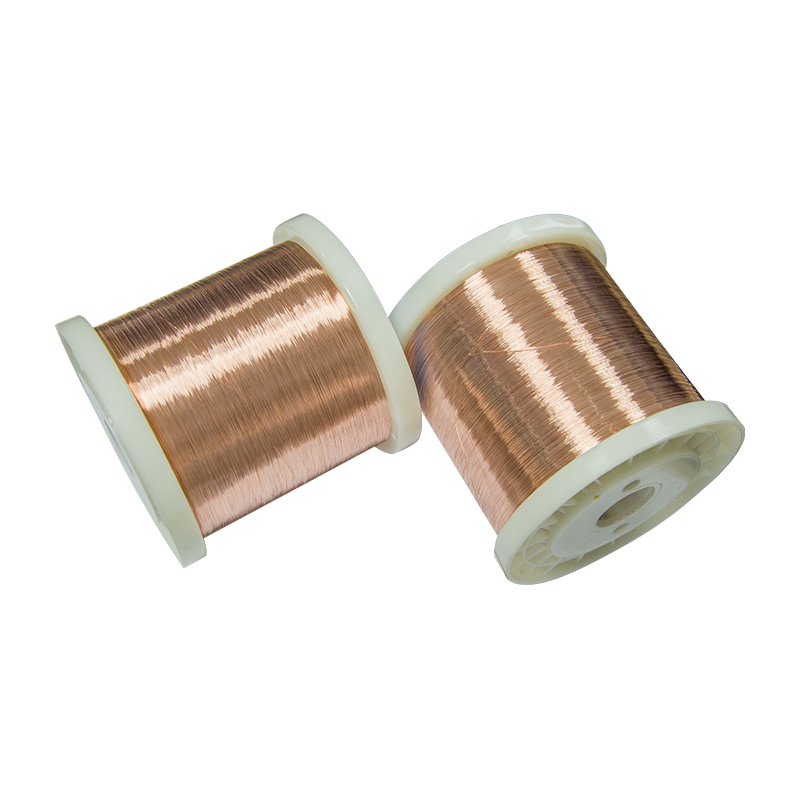

Waya dzeDia 0.6mm Alloy M25 Copper Beryllium dzeContact Bridges

Tsananguro yeChigadzirwa

Kuumbwa kweMakemikoro (Pasenti yeHuremu) yeC17200 Beryllium Copper Alloy:

| Kupa Mhinduro | ||||||

| chiwanikwa | Beryllium | Cobalt | Nickel | Co + Ni | Co+Ni+Fe | Mhangura |

| C17200 | 1.80-2.00 | - | 0.20 Min | 0.20 Min | 0.60 Max | Kuenzana |

Chirevo: Kuwedzera kwemhangura pamwe chete kwakaenzana ne99.5% Min.

THunhu hwepanyama hweC172:

Kuwanda (g/cm3): 8.36

Kuwanda kweganda risati raoma (g/cm3): 8.25

Elastic Modulus (kg/mm2 (103)): 13.40

Kuwedzerwa kweThermal Coefficient (20 °C kusvika 200 °C m/m/°C): 17 x 10-6

Kufambisa kwekupisa (cal/(cm-s-°C)): 0.25

Kunyunguduka Kwemvura (°C): 870-980

Hasha Dzakajairika dzatinopa:

| Kusarudzwa kweCuBeryllium | ASTM | Hunhu hweCopper Beryllium Strip neMagetsi | ||||||

| Kugadzwa | Tsananguro | Simba reKusimba (Mpa) | Simba reGoho 0.2% kuderedzwa | Kureba kwezana | KUOMA (HV) | KUOMA Rockwell Chikero cheB kana C | Kufambisa Kwemagetsi (% IACS) | |

| A | TB00 | Mhinduro Yakabviswa | 410~530 | 190~380 | 35~60 | <130 | 45~78HRB | 15~19 |

| 1/2 H | TD02 | Hafu Yakaoma | 580~690 | 510~660 | 12~30 | 180~220 | 88~96HRB | 15~19 |

| H | TD04 | Zvakaoma | 680~830 | 620~800 | 2~18 | 220~240 | 96~102HRB | 15~19 |

| HM | TM04 | Chigayo chakaomarara | 930~1040 | 750~940 | 9~20 | 270~325 | 28~35HRC | 17~28 |

| SHM | TM05 | 1030~1110 | 860~970 | 9~18 | 295~350 | 31~37HRC | 17~28 | |

| XHM | TM06 | 1060~1210 | 930~1180 | 4~15 | 300~360 | 32~38HRC | 17~28 | |

Tekinoroji Inokosha yeBeryllium Copper (Kurapa kupisa)

Kurapa nekupisa ndiyo nzira inonyanya kukosha kune iyi alloy system. Kunyange hazvo alloys dzese dzemhangura dzichiomarara nekushanda muchando, beryllium copper yakasiyana nekuomarara nekupisa kuri nyore. Inosanganisira matanho maviri ekutanga. Yekutanga inonzi solution annealing uye yechipiri, precipitation kana age hardening.

Kugadziriswa kweMhinduro

Kune alloy yakajairika CuBe1.9 (1.8- 2%) alloy inopiswa pakati pe720°C ne860°C. Panguva ino beryllium iri mukati inonyungudika "mu" copper matrix (alpha phase). Nekudzima nekukurumidza kusvika patembiricha yemukamuri, chimiro chemhinduro chakasimba chinochengetwa. Chinhu chiri padanho iri chakapfava uye chinopfava uye chinogona kutonhora zviri nyore kushanda nekudhirowa, kugadzira kutenderera, kana kutonhora. Kushanda kwe solution annealing chikamu chemaitiro pamill uye hachiwanzo shandiswa nemutengi. Tembiricha, nguva patembiricha, quench rate, saizi yegrain, uye kuomarara zvese zviyero zvakakosha uye zvinodzorwa zvakasimba neTANKII.

Kuomesa Kwezera

Kuomesa zvinhu panguva yekukwegura kunowedzera simba razvo zvakanyanya. Izvi zvinowanzoitwa patembiricha iri pakati pe260°C ne540°C zvichienderana nealloy uye hunhu hwaunoda. Kutenderera uku kunoita kuti beryllium yakanyungudutswa iite sechikamu cheberyllium (gamma) chakapfuma mu matrix uye pamiganhu yetsanga. Kuumbwa kweprecipitate iyi ndiko kunokonzera kuwedzera kukuru kwesimba rezvinhu. Hunhu hwemakanika hunowanikwa hunotsanangurwa netembiricha nenguva patembiricha. Zvinofanira kucherechedzwa kuti beryllium copper haina hunhu hwekukwegura patembiricha yemumba.

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro