CuSn4 CuSn6 CuSn8 Phosphor Tin Bronze Coil Strip C5191

CuSn4 CuSn6 CuSn8 Phosphor Tin Bronze Coil Strip C5191 Tsanangudzo:

CuSn4 CuSn6 CuSn8 Phosphor Tin Bronze Coil Strip

CuSn6 - UNS.C51900 Phosphor Bronze Alloys, inova 6% tin bronze ine simba rakawanda uye inochinja-chinja magetsi. Inoshandiswa kumasprings anobatana uye anotakura magetsi ari mu contacts. Pakati pe4-8% tin bronze C51900 ine simba remagetsi rakawanda, simba rayo guru rinosvikika rakakwirira kupfuura C51100 neC51000. Nekushandisa imwe tenpering mushure mekuumbwa kwechando, kugona kuchinjika kunogona kuvandudzwa zvakanyanya.

Phosphor Bronze C51900 Kuumbwa kwemakemikari

| Zvinyorwa | Kuumbwa kwemakemikari | |||||

| GB | UNS | EN | JIS | Cu% | Sn% | P% |

| QSn6.5-0.1 | C51900 | CuSn6 | C5191 | Rem | 5.5-7.0 | 0.03-0.35 |

| Kuumbwa kweMakemikari | |||

| % | |||

| Sn | P | Cu | kusviba |

| 7.0~9.0 | 0.15~0.35 | Bhari. | ≤0.1 |

Zvimiro zvePhosphor Bronze Mechanical

| Zvivakwa zveMichina | |||||

| Hasha | TS(N/mm²) | Kureba (%) | Kuoma (Hv) | ||

| M | O | O60 | ≥345 | ≥40 | / |

| Y4 | 1/4H | H01 | 390-510 | ≥35 | 100-160 |

| Y2 | 1/2H | H02 | 490-610 | ≥8 | 150-200 |

| Y | H | H04 | 590-705 | ≥5 | 190-230 |

| T | EH | H06 | 585-740 | / | 200-240 |

| TY | SH | H08 | ≥735 | / | ≥230 |

| Hunhu hwemakanika | |||||||

| Nyika | Kuoma (HV) | Kuedza kwekuneta | Bvunzo rekukombama | ||||

| ukobvu mm | simba rekudhonza MPa | kureba % | ukobvu | makona | ID | ||

| 0 | - | 0.1-5.0 | ≥315 | ≥42 | ≤1.6 | 180° | 50% yeukobvu |

| 1/4H | 100-160 | 0.1-5.0 | 390-510 | ≥35 | ≤1.6 | 180° | 100% yeukobvu |

| 1/2H | 150-205 | 0.1-5.0 | 490-610 | ≥20 | ≤1.6 | 180° | 150% yeukobvu |

| H | 180-230 | 0.1-5.0 | 590-685 | ≥8 | ≤1.6 | 180° | 200% yeukobvu |

| EH | 200-240 | 0.1-0.2 | 635-720 | - | - | - | - |

| >0.2-5 | ≥5 | - | - | - | |||

| SH | ≥210 | 0.1-5.0 | ≥690 | - | - | - | - |

Zvimiro zvePhosphor Bronze C51900 zvePhosphor Bronze Strips

- Mwero wekureba ≥25%

- Modulus yekusimba: 125GPa

- Simba rekupa: ≥90% simba rekusimba

- Kushanda kwekuneta

- Kugadzirwa kwepurasitiki

- Kushanda kwakanaka kwazvo kwekushongedza

- Kushanda zvakanaka kwechando, hunyanzvi hwekudhirowa hwakadzika, hunyanzvi hwekuchinjika

Phosphor Bronze C51900 Kushandiswa kwakajairika

Phosphor Bronze inoshandiswa zvakanyanya muCPU slot yekomputa, terminal yemotokari, mabhatani efoni, zvinobatanidza zvemagetsi uye mamwe masisitimu emagetsi epamusoro-soro.

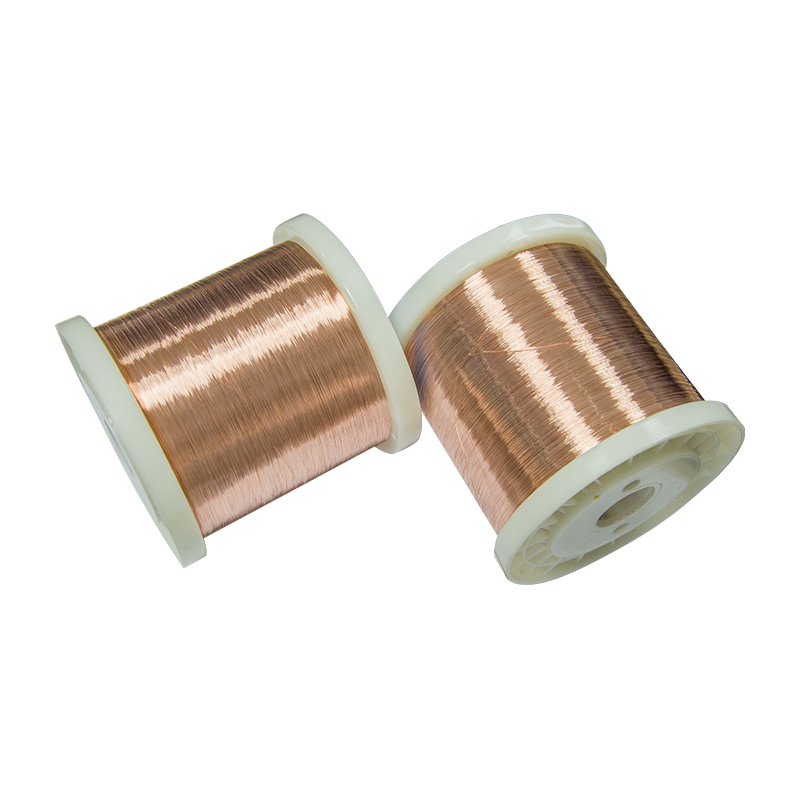

Mifananidzo yezvigadzirwa:

Gwaro Rechigadzirwa Rinoenderana:

Tinotora "zvinoenderana nevatengi, zvine hunhu hwakanaka, zvinobatanidza, uye zvine hunyanzvi" sezvinangwa. "Chokwadi nekuvimbika" ndiyo nzira yedu yekutarisira CuSn4 CuSn6 CuSn8 Phosphor Tin Bronze Coil Strip C5191, Chigadzirwa ichi chichapihwa kune vese pasi rese, senge: Colombia, Rwanda, Angola, Tinogona kusangana nezvinodiwa nevatengi vari kumba nekune dzimwe nyika. Tinogamuchira vatengi vatsva nevakare kuti vauye kuzobvunzana nesu uye kutaurirana nesu. Kugutsikana kwenyu ndiko kwatinokurudzira! Ngatishandei pamwe chete kuti tinyore chitsauko chitsva chinoshamisa!

Vashandi vebasa revatengi nevatengesi vane mwoyo murefu uye vese vanogona Chirungu, kusvika kwechigadzirwa kunouyawo nenguva, mutengesi akanaka.

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro