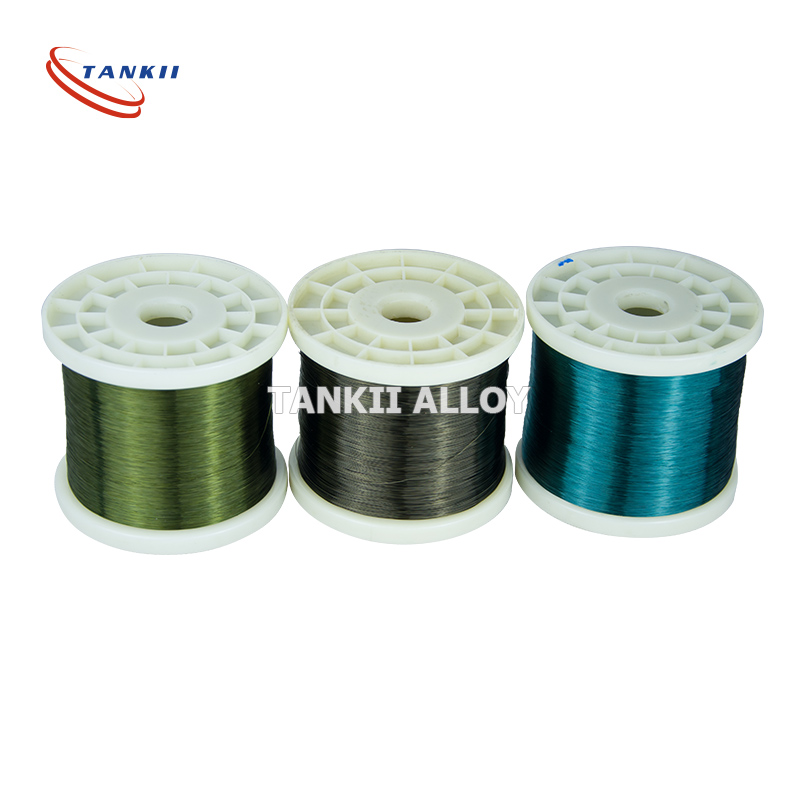

waya yemhangura inopisa kirasi C / 200*C ANSI TYPE MW35C kana IEC 317-13. Waya inomonereka ine enamel yakapetwa kaviri ine polyester-imide ne polyamide-imide

waya yemhangura kirasi yekupisa C/ 200*C ANSI TYPE MW35C kana IEC 317-13. Polyester-imide uyepolyamide-imidewaya inomonereka yakapetwa kaviri

Tsananguro yeChigadzirwa

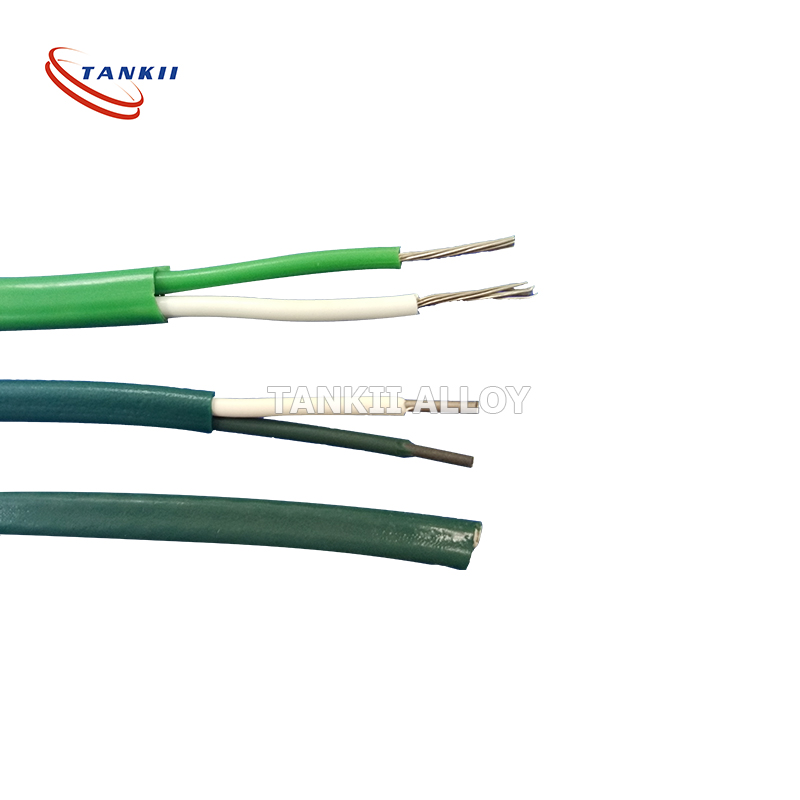

Waya idzi dzinodzivirira dzakashandiswa zvakanyanya pakushandisa ma resistors akajairwa, mota

zvikamu, zvinodzivirira kutenderera, nezvimwewo uchishandisakuputirakugadziriswa kwakanyatsokodzera mashandisirwo aya, vachishandisa zvizere hunhu hwakasiyana hwe enamel coating.

Uyezve, tichagadzira enamel coating.kuputirawaya dzesimbi dzinokosha dzakadai sesirivha neplatinum kana watenga. Ndapota shandisai iyi yekugadzira-pa-odha.

Rudzi rweNichrome Wire

NiCr80/20,NiCr70/30,NiCr60/15,NiCr90/10,NiCr35/20,NiCr30/20

Rudzi rwekudzivirira

| Zita rakaiswa muchina wekudzivirira kupisa | Huremu hwekupisaºC (Nguva yekushanda 2000h) | Zita reKodhi | Kodhi yeGB | Rudzi rweANSI |

| Waya ye polyurethane enamelled | 130 | UEW | QA | MW75C |

| Waya ine enamel yepolyester | 155 | PEW | QZ | MW5C |

| Waya ine enamel yepolyester-imide | 180 | EIW | QZY | MW30C |

| Waya ine enamel yakapetwa kaviri yakagadzirwa nepolyester-imide nepolyamide-imide | 200 | EIWH (DFWF) | QZY/XY | MW35C |

| Waya ye polyamide enamelled | 220 | AIW | QXY | MW81C |

Rudzi rweWaya yeAlloy isina chinhu

Chidimbu chatinogona kuita chine enamelled zvinosanganisira waya yeCopper-nickel alloy, waya yeConstantan, waya yeManganin. Waya yeKama, waya yeNiCr Alloy, waya yeFeCrAl Alloy nezvimwewo.

| chikuru pfuma mhando | Cuni1 | CuNI2 | CuNI6 | CuNi8 | CuNI10 | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNI44 | ||

| chikuru kemikari kuumbwa | Ni | 1 | 2 | 6 | 8 | 10 | 14.2 | 19 | 23 | 30 | 34 | 44 | |

| MN | / | / | / | / | / | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | ||

| CU | zororo | zororo | zororo | zororo | zororo | zororo | zororo | zororo | zororo | zororo | zororo | ||

| zvakanyanya kushanda tembiricha | / | 200 | 220 | 250 | 250 | 300 | 300 | 300 | 350 | 350 | 400 | ||

| kuwanda g/cm3 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | ||

| kuramba pa20 °c | 0.03 ± 10% | 0.05± 10% | 0.10± 10% | 0.12± 10% | 0.15± 10% | 0.20± 5% | 0.25± 5% | 0.30± 5% | 0.35± 5% | 0.40± 5% | 0.49± 5% | ||

| tembiricha chiyero che kuramba | <100 | <120 | <60 | <57 | <50 | <38 | <25 | <16 | <10 | -0 | <-6 | ||

| kusimbaradza simba rempa | >210 | >220 | >250 | >270 | >290 | >310 | >340 | >350 | >400 | >400 | >420 | ||

| kureba | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | ||

| kunyunguduka poindi °c | 1085 | 1090 | 1095 | 1097 | 1100 | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | ||

| chiyero che kutenderera kwemhepo | 145 | 130 | 92 | 75 | 59 | 48 | 38 | 33 | 27 | 25 | 23 |

waya yekudziyisa yenicr8020 alloy

1. Nezve waya yeNichrome

Chiumbwa cheNichrome chinosanganisira pure nickel, NiCr alloy, Fe-Cr-Al alloy uye copper nickel alloy.

Nickel chrome alloys: Ni80Cr20, Ni70Cr30, Ni60Cr15, Ni35Cr20, Ni30Cr20, Cr25Ni20, pure nickel Ni200 uye Ni201

2. Main Advantage uye Application

1. Nickel-chromium, nickel-chromium alloy ine simba rakasimba uye rakagadzikana, inodzivirira ngura, inodzivirira oxidation pamusoro, ine simba rakanaka kana tembiricha yakakwira uye simba rekudengenyeka kwenyika, ine ductility yakanaka, inoshanda zvakanaka uye inogona kusvetwa.

2. Zvigadzirwa zvedu zvinoshanda zvakanyanya muindasitiri yemakemikari, michina yesimbi, indasitiri yegirazi, indasitiri yeceramic, nzvimbo yemidziyo yemumba nezvimwewo.

3. Kuumbwa kwemakemikari:

| Rudzi | Kuumbwa kwemakemikari | Si | Cr | Ni | Al | Fe | |||

| C | P | S | Mn | ||||||

| Kwete kupfuura | |||||||||

| Cr20Ni80 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 20.0-23.0 | ramba | ≤0.50 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 15.0-18.0 | 55.0-61.0 | ≤0.50 | ramba |

| Cr20Ni35 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-3.00 | 18.0-21.0 | 34.0-37.0 | - | ramba |

| Cr20Ni30 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-2.00 | 18.0-21.0 | 30.0-34.0 | - | ramba |

Kana chigadzirwa chiri pa "M", chinofanira kuteverwa ne GB/T1234-1995 yakajairwa

Kuramba:

| Rudzi | Cr20Ni80 | Cr20Ni60 | Cr20Ni35 | Cr20Ni30 | ||

| Dhayamita mm | <0.50 | 0.50-3.0 | <0.50 | ≥0.50 | <0.50 | ≥0.50 |

| kusimba (20°C)uΩ·m | 1.09±0.05 | 1.13±0.05 | 1.12±0.05 | 1.15±0.05 | 1.04±0.05 | 1.06±0.05 |

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro