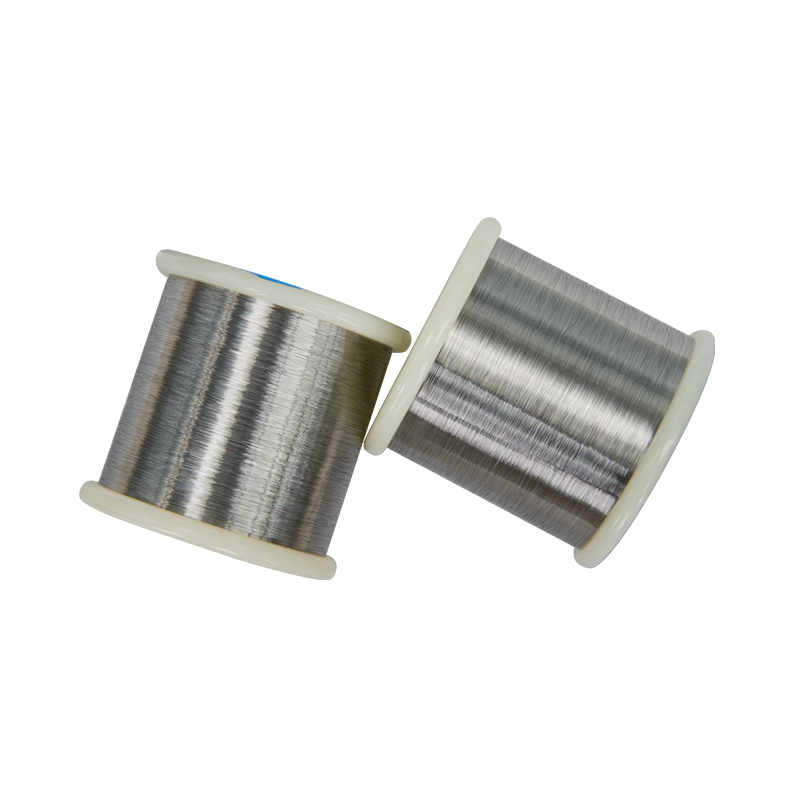

Aws A5.14 Nickel Alloy Ernicu-7 MIG Welding Wire TIG Welding Rod yeMonel 400 Welding

1. FM60 Oxford Alloy 60ERNiCu-7Tsvimbo yekunamira yeTIG

ERNiCu-7 ine simba rakanaka uye inodzivirira ngura mune zvakawanda, kusanganisira mvura yegungwa, munyu, uye kuderedza acids. Uye inogona kushandiswa kufukidza simbi yekabhoni, chero bedzi ERNi-1 yakashandiswa pachikamu chekutanga. Chiumbwa ichi hachiomeswi nekukwegura uye kana chikashandiswa kubatanidza Monel K-500 chine simba shoma pane simbi yekutanga.

Mazita Anowanzo shandiswa: Oxford Alloy® 60 FM 60 Techalloy 418

Standard: AWS 5.14 Kirasi ERNiCu-7 / ASME SFA 5.14 Kirasi ERNiCu-7 ASME II, SFA-5.14 UNS N04060 Werkstoff Nr. 2.4377 ISO SNi4060 Europe NiCu30Mn3Ti

KUUMBIKA KWEMAKEMIKIRI(%)

| C | Si | Mn | S | P | Ni |

| ≤0.15 | ≤1.25 | ≤4.0 | ≤0.015 | ≤0.02 | 62-69 |

| Al | Ti | Fe | Cu | vamwe | |

| ≤1.25 | 1.5-3.0 | ≤2.5 | Zorora | <0.5 |

ZVIGADZIRWA ZVEKUWEDZERA

| Maitiro | Dhayamita | Voltage | Amperage | Gasi |

| TIG | .035″ (0.9mm) .045″ (1.2mm) 1/16″ (1.6mm) 3/32″ (2.4mm) 1/8″ (3.2mm) | 12-15 13-16 14-18 15-20 15-20 | 60-90 80-110 90-130 120-175 150-220 | 100% Argon 100% Argon 100% Argon 100% Argon 100% Argon |

| MIG | .035″ (0.9mm) .045″ (1.2mm) 1/16″ (1.6mm) | 26-29 28-32 29-33 | 150-190 180-220 200-250 | 75% Argon+25% Helium 75% Argon+25% Helium 75% Argon + 25% Helium |

| SAW | 3/32″ (2.4mm) 1/8″ (3.2mm) 5/32″ (4.0mm) | 28-30 29-32 30-33 | 275-350 350-450 400-550 | Flux yakakodzera inogona kushandiswa Flux yakakodzera inogona kushandiswa Flux yakakodzera inogona kushandiswa |

ZVINHU ZVEMAKANIKISI

| Simba reKusimba | 76,5000 PSI | 530 MPA |

| Simba reGoho | 52,500 PSI | 360 MPA |

| Kureba | 34% |

ZVINOSHANDISWA

ERNiCu-7 inogona kushandiswa pakushongedza zvinhu zvakasiyana-siyana uchishandisa nickel-copper alloys dzakasiyana-siyana kusvika ku nickel 200 uye copper-nickel alloys.

ERNiCu-7 inoshandiswa pakusanganisa gas-tungsten-arc, gas-metal-arc, uye submerged-arc welding yeMonel alloy 400 neK-500.

ERNiCu-7 inoshandiswa zvakanyanya mukushandiswa kwemvura yemugungwa nekuda kwekusagona kwayo kukuvadza mvura yemugungwa nemvura ine munyu.

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro