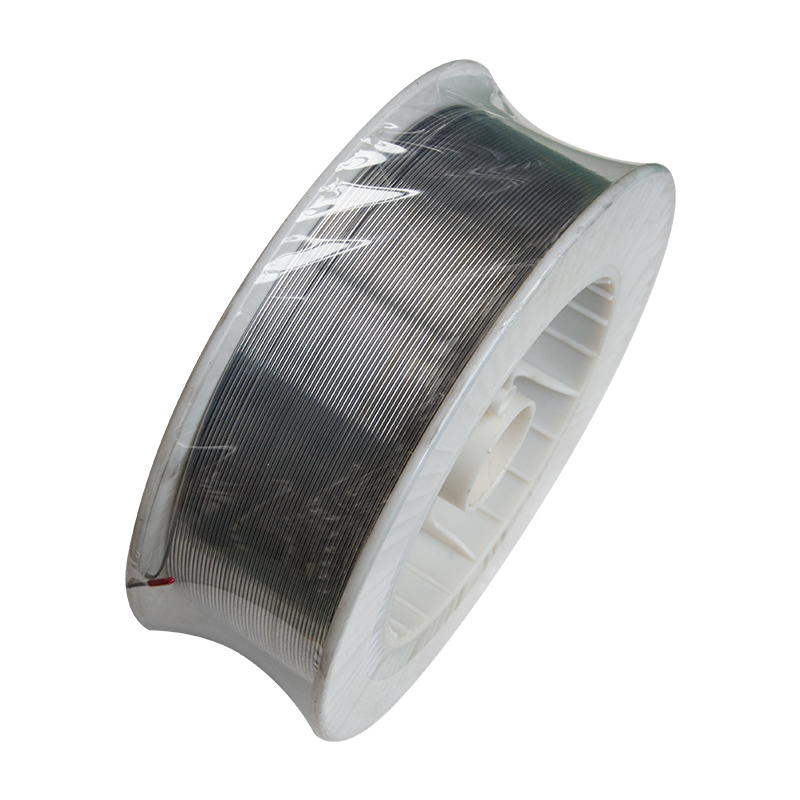

ASME Sfa 5.14 Ernicr-3 Nickel Alloy 80 Inconel 600 Alloy MIG Welding Wire TIG Welding Rod

Inconel 600 is nickel-chromium alloy ine kupikisa kwakanyanya kune organic acids uye inoshandiswa zvakanyanya mumafuta acid kugadzirisa. Iyo yakakwira nickel yemukati yeInconel 600 inopa kuramba kwakanaka kune ngura pasi pekudzikisa mamiriro, uye yayo chromium yemukati, kuramba pasi pe oxidizing mamiriro. Iyo alloy inenge isingadzivirirwe kune chloride stress-corrosion cracking. Inoshandiswawo zvakanyanya mukugadzira uye kubata kwecaustic soda uye alkali makemikari. Alloy 600 zvakare chinhu chakanakisa chepamusoro-tembiricha maapplication anoda musanganiswa wekupisa uye kushora kuramba. Kuita kwakanakisa kweiyo alloy munzvimbo inopisa halogen inoita kuti ive sarudzo yakakurumbira kune organic chlorination maitiro. Alloy 600 zvakare inopikisa oxidation, carburization, uye nitridation.

Mukugadzirwa kwetitanium dioxide nekloride nzira dzinongoitika titanium oxide (illmenite kana rutile) uye inopisa chlorine magasi akaita kuti abudise titanium tetrachloride. Alloy 600 yakashandiswa zvinobudirira mukuita uku nekuda kwekupokana kwayo kwekuora nekupisa chlorine gasi. Iyi alloy yakawana kushandiswa kwakakura muchoto uye nzvimbo yekupisa kupisa nekuda kwekugona kwayo kupikisa oxidation uye kuyera pa980 ° C. Iyo alloy yakawanawo kushandiswa kwakanyanya mukubata nharaunda dzemvura, uko simbi dzisina tsvina dzakakundikana nekutsemuka. Yakashandiswa muhuwandu hwenyukireya reactor zvinosanganisira steam jenareta kubikira uye yekutanga mvura pombi masisitimu.

Zvimwe zvinowanzoitika midziyo yekugadzira makemikari uye pombi, midziyo yekupisa kupisa, injini yendege uye zvikamu zveairframe, zvikamu zvemagetsi, uye mareactor enyukireya.

Kuumbwa Kwemakemikari

| Giredhi | Ni% | Mn% | Fe% | Si% | Cr% | C% | Cu% | S% |

| Inconel 600 | Min 72.0 | Max 1.0 | 6.0-10.0 | Max 0.50 | 14-17 | Max 0.15 | Max 0.50 | Hurefu 0.015 |

Zvinotsanangurwa

| Giredhi | British Standard | Werkstoff Nr. | UNS |

| Inconel 600 | BS 3075 (NA14) | 2.4816 | N06600 |

Zvinhu Zvenyama

| Giredhi | Density | Melting Point |

| Inconel 600 | 8.47 g/cm3 | 1370°C-1413 °C |

Mechanical Properties

| Inconel 600 | Tensile Simba | Goho Simba | Elongation | Brinell Kuoma (HB) |

| Annealing Treatment | 550 N/mm² | 240 N/mm² | 30% | ≤195 |

| Solution Kurapa | 500 N/mm² | 180 N/mm² | 35% | ≤185 |

Yedu Production Standard

| Bar | Forging | Pipe | Sheet/Mutsetse | Waya | Fittings | |

| ASTM | ASTM B166 | ASTM B564 | ASTM B167/B163/B516/B517 | AMS B168 | ASTM B166 | ASTM B366 |

Welding yeInconel 600

Chero tsika dzechinyakare dzekushongedza dzinogona kushandiswa kupinza Inconel 600 kune akafanana alloys kana mamwe simbi. Pamberi pekuputira, preheating inodiwa uye zvakare chero tsvina, guruva kana chiratidzo chinofanira kucheneswa nesimbi waya brashi. Inenge 25mm hupamhi kusvika kumucheto wewelding yesimbi yepasi inofanira kukwenenzverwa kupenya.

Kurudzira mafirita waya nezve welding Inconel 600: ERNiCr-3

Zvigadzirwa zvikamu

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top