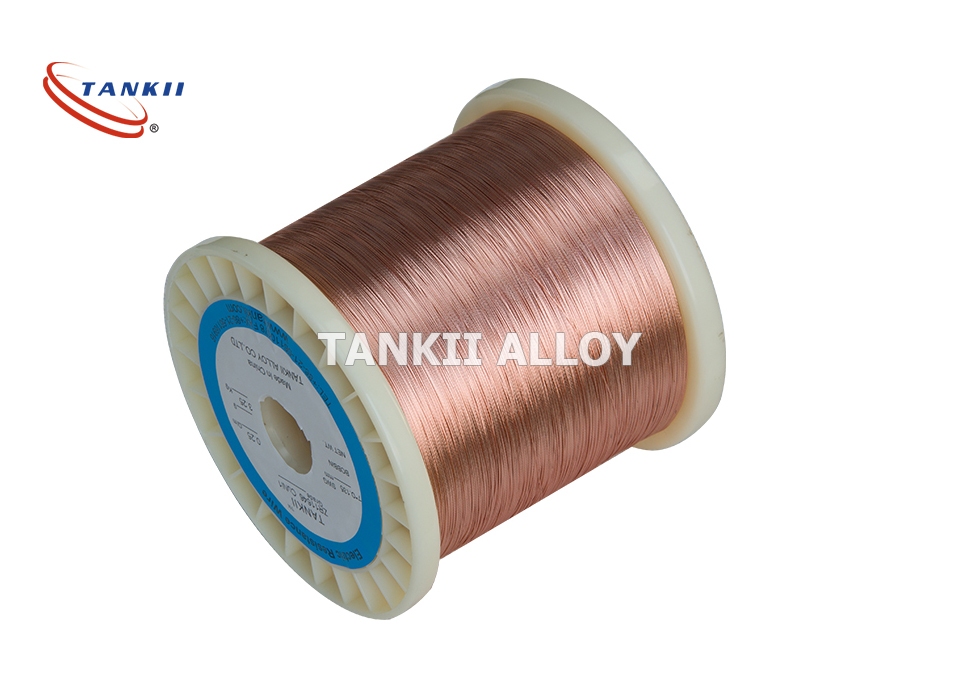

Chibage 180 Manganin Insulated Enameled Copper Nickel CuNi Resistance Wire

Nicr Yakavakirwa Pamhangura YakatendereraChiwanikwa 180Waya yemhangura yakaputirwa neEnameled yedhigirii

1. Tsananguro Yese Yezvinhu

1)

Manganinimhando yesimbi inowanzo kuve ne 84% mhangura, 12% manganese, uye 4% nickel.

Waya dzeManganin nefoil zvinoshandiswa mukugadzira maresistor, kunyanya ammeter shunt, nekuda kwekusagadzikana kwayo kwekupisa uye kugadzikana kwenguva refu. MaManganin resistors akati wandei akashanda sechiyero chepamutemo cheohm muUnited States kubva 1901 kusvika 1990. Waya dzeManganin dzinoshandiswawo semuchina wemagetsi mumasisitimu e cryogenic, zvichideredza kutamiswa kwekupisa pakati penzvimbo dzinoda kubatana kwemagetsi.

Manganin inoshandiswawo mumagauge ekuongorora mafungu ekuvhunduka ane simba guru (akadai seaya anokonzerwa nekuputika kwezvinoputika) nekuti ine simba shoma asi ine simba rakawanda rehydrostatic pressure.

2)

Constantanisimbi yemhangura-nickel inozivikanwawo seEureka, PamberiuyeChikepeKazhinji ine 55% yemhangura uye 45% nickel. Chinhu chikuru chayo ndechekudzivirira kwayo, iyo inogara iripo pakupisa kwakasiyana-siyana. Mamwe ma alloys ane ma coefficients akafanana ekupisa kwakaderera anozivikanwa, akadai semanganin (Cu).86Mn12Ni2).

Pakuyerwa kwemhando dzakakura kwazvo, 5% (50 000 microstrian) kana kupfuura, annealed constantan (P alloy) ndiyo grid material inowanzo sarudzwa. Constantan muchimiro ichi inopfava zvakanyanya; uye, muhurefu hwegauge hwe 0.125 inches (3.2 mm) uye kureba, inogona kumanikidzwa kusvika >20%. Zvisinei, zvinofanira kurangarirwa kuti pasi pemhando dzakakwira dzecyclic alloy P icharatidza shanduko inogara iripo nekutenderera kwegauge yegauge, uye inokonzera zero shift inoenderana mu strain gauge. Nekuda kwehunhu uhwu, uye katsika kekukundikana kwegrid nguva isati yakwana nekumanikidzwa kudzokorora, P alloy haiwanzo kukurudzirwa kushandiswa kwe cyclic strain. P alloy inowanikwa neSTC nhamba dze 08 ne 40 dzekushandiswa pasimbi nemapurasitiki, zvichiteerana.

2. Nhanganyaya yeWaya Yakasanganiswa uye mashandisirwo ayo

Kunyangwe ichitsanangurwa se "enameled", waya ye enamel haina kuputirwa nependi ye enamel kana kuti ne vitreous enamel yakagadzirwa nehupfu hwegirazi hwakasanganiswa. Waya yemazuva ano yemagineti inowanzo shandisa jira rimwe kusvika mana (kana iri waya yemhando ye quad-film) ye polymer film insulation, kazhinji yemhando mbiri dzakasiyana, kupa jira rakasimba, rinogara richidzivirira. Mafirimu e magnet wire insulation anoshandisa (mukutevedzana kwekuwedzera kwekupisa) polyvinyl formal (Formar), polyurethane, polyimide, polyamide, polyamide, polyster, polyester-polyimide, polyamide-polyimide (kana amide-imide), uye polyimide. Waya yemagineti yakaputirwa ne polyimide inokwanisa kushanda kusvika 250 °C. Kudzivirira kwewaya yemagineti yakakora kana ye rectangular kunowanzo wedzerwa nekuiputira ne polyimide kana fiberglass tape ine tembiricha yepamusoro, uye ma windings akapedzwa anowanzo putirwa ne vacuum ne insulation varnish kuti ivandudze simba re insulation uye kuvimbika kwenguva refu kwe winding.

Makoiri anozvitsigira anoputirwa newaya yakafukidzwa nezvikamu zviviri, chikamu chekunze chiri thermoplastic inobatanidza matenderedzwa acho pamwe chete kana apiswa.

Mamwe marudzi ekudzivirira kupisa akadai seshinda yefiberglass ine varnish, bepa rearamid, bepa rekraft, mica, uye firimu repolyester anoshandiswawo zvakanyanya pasi rese mukushandiswa kwakasiyana-siyana senge ma transformer nema reactors. Muchikamu cheaudio, waya yesirivha yakagadzirwa, nezvimwe zvakasiyana-siyana zvinodzivirira kupisa, zvakaita sedonje (dzimwe nguva zvinozadzwa neimwe mhando ye coagulating agent/thickener, senge beewax) uye polytetrafluoroethylene (PTFE) zvinogona kuwanikwa. Zvinhu zvekare zvinodzivirira kupisa zvinosanganisira donje, bepa, kana sirika, asi izvi zvinongobatsira chete pakushandiswa kwekupisa kwakaderera (kusvika 105°C).

Kuti zvive nyore kugadzira, dzimwe waya dzemagineti dzine tembiricha yakaderera dzine insulation inogona kubviswa nekupisa kwekunamira. Izvi zvinoreva kuti kubatana kwemagetsi kumagumo kunogona kuitwa pasina kubvisa insulation kutanga.

3.Kuumbwa kweChemical uye Hunhu Hukuru hweCu-Ni Low Resistance Alloy

| Grade yeZvivakwa | CuNi1 | CuNi2 | CuNi6 | CuNi8 | CuMn3 | CuNi10 | |

| Kuumbwa Kwemakemikari Main | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | Bhari | Bhari | Bhari | Bhari | Bhari | Bhari | |

| Tembiricha Yepamusoro Yebasa Rinoenderera Mberi (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Kusimba kwesimba pa20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Kuwanda (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Kufambisa kwekupisa (α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Simba reKusimba (Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Nzvimbo Inofungidzirwa Yekunyunguduka (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Maumbirwo eMicrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Pfuma yeMagineti | kwete | kwete | kwete | kwete | kwete | kwete | |

| Grade yeZvivakwa | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNi44 | |

| Kuumbwa Kwemakemikari Main | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | Bhari | Bhari | Bhari | Bhari | Bhari | Bhari | |

| Tembiricha Yepamusoro Yebasa Rinoenderera Mberi (oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Kusimba kwesimba pa20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Kuwanda (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Kufambisa kwekupisa (α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Simba reKusimba (Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Nzvimbo Inofungidzirwa Yekunyunguduka (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Maumbirwo eMicrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Pfuma yeMagineti | kwete | kwete | kwete | kwete | kwete | kwete | |

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro