Tinokugamuchirai kumawebhusaiti edu!

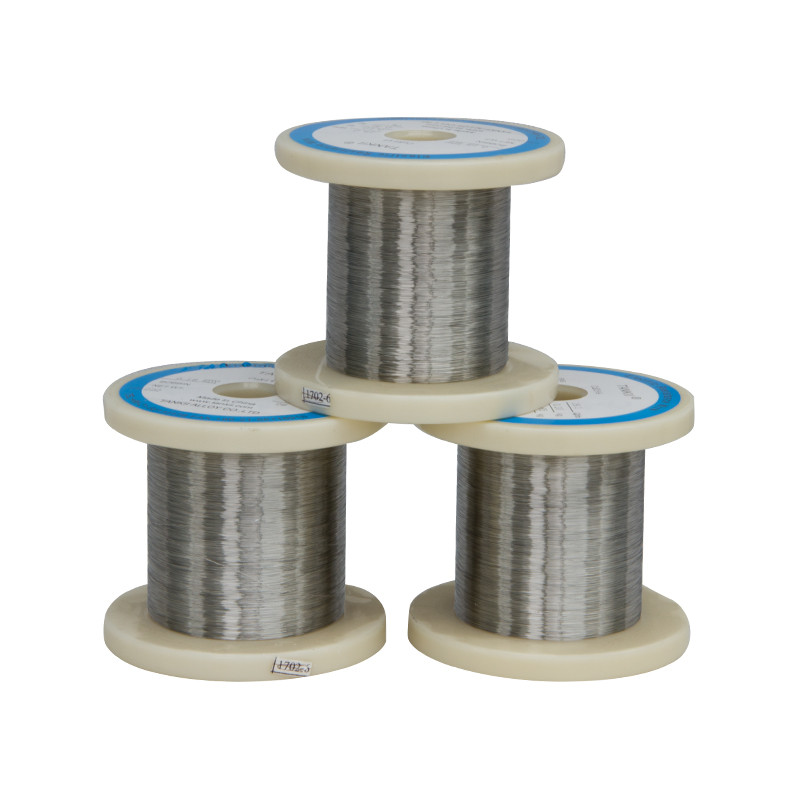

1j77 Waya yeMagnetic Alloy yakapfava Ni77Mo4Cu5

Zvakajairika%

| Ni | 75.5~78 | Fe | Bhari. | Mn | 0.3~0.6 | Si | 0.15~0.3 |

| Mo | 3.9~4.5 | Cu | 4.8~6.0 | ||||

| C | ≤0.03 | P | ≤0.02 | S | ≤0.02 |

Zvimiro zveMichina zvakajairika

| Simba rekupa | Simba reKusimba | Kureba |

| Mpa | Mpa | % |

| 980 | 980 | 2~40 |

Zvimiro zvepanyama zvakajairika

| Kuwanda (g/cm3) | 8.6 |

| Kudzivirira kwemagetsi pa20ºC(Om*mm2/m) | 0.55 |

| Kuwedzerwa kwemutsetse kweCoefficient (20ºC ~ 200ºC) X10-6/ºC | 10.3~11.5 |

| Kuzara kwesimba remagineti λθ/ 10-6 | 2.4 |

| Nzvimbo yeCurie Tc/ºC | 350 |

| Hunhu hwemagineti hwema alloys ane mukana wakakwira muminda isina simba | |||||||

| Ni77Mo4Cu5 | Kubvumidzwa kwekutanga | Kubvumidzwa kwakanyanya | Kumanikidza | Kuzara kwesimba remagineti ekugadzira | |||

| Chidimbu chakapetwa chekare/pepa. Ukobvu, mm | μ0.08/ (mH/m) | μm/ (mH/m) | Hc/ (A/m) | BS/ T | |||

| ≥ | ≤ | ||||||

| 0.01 mm | 17.5 | 87.5 | 5.6 | 0.75 | |||

| 0.1~0.19 mm | 25.0 | 162.5 | 2.4 | ||||

| 0.2~0.34 mm | 28.0 | 225.0 | 1.6 | ||||

| 0.35~1.0 mm | 30.0 | 250.0 | 1.6 | ||||

| 1.1 ~ 2.5 mm | 27.5 | 225.0 | 1.6 | ||||

| 2.6~3.0 mm | 26.3 | 187.5 | 2.0 | ||||

| waya inotonhorera | |||||||

| 0.1 mm | 6.3 | 50 | 6.4 | ||||

| Bhawa | |||||||

| 8-100 mm | 25 | 100 | 3.2 | ||||

| Nzira yekurapa kupisa Ni77Mo4Cu5 | |

| Kunyudza midhiya | Vhuku ine simba rekubvisa simbi risingapfuure 0.1Pa, hydrogen ine dova risingapfuure 40 ºC. |

| Tembiricha yekupisa uye mwero | 1100~1150ºC |

| Nguva yekubata | 3~6 |

| Mwero wekutonhora | Kana yatonhodzwa kusvika pa600 ºC, inotonhodzwa nekukurumidza kusvika pa300ºC |

Nyora meseji yako pano woitumira kwatiri

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro