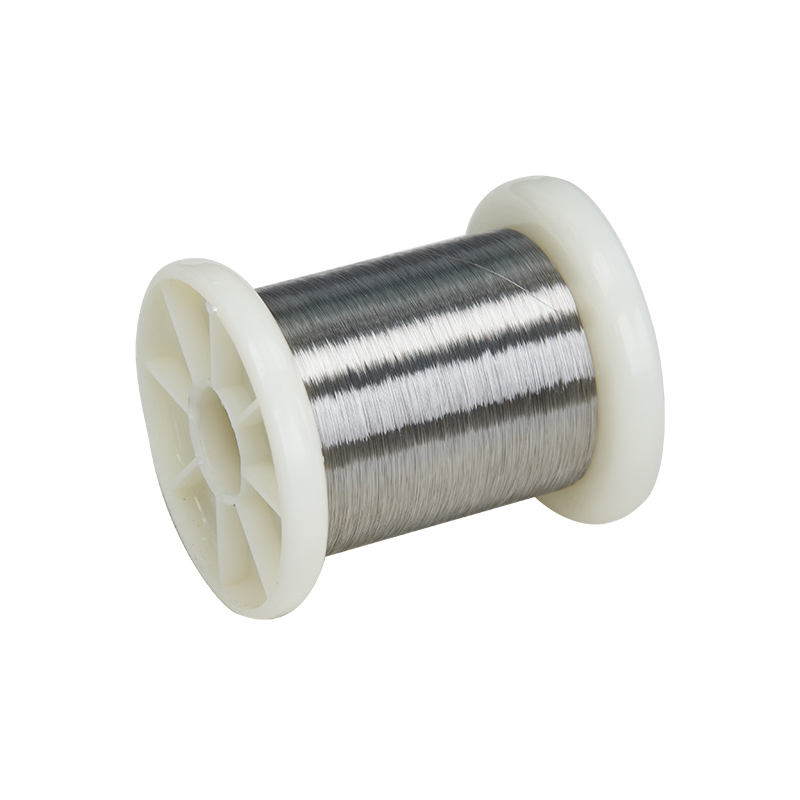

FeNi80 / Ni80Mo5/Soft Magnetic Alloy Hymu80 Waya Ni79Mo4 permalloy 80 waya

Inonyanya kushandiswa munzvimbo mbiri dzekushandura simba uye kugadzirisa ruzivo

Muindasitiri yemagetsi, kunyanya mumunda wemagetsi une simba guru remagineti uye kurasikirwa kwakaderera kwesimbi. Muindasitiri yemagetsi, kunyanya musimbi yakaderera kana yepakati ine simba guru remagineti uye simba shoma rekumanikidza. Pamafrequencies akakwirira, simbi yakatetepa kana simbi inofanira kugadzirwa nesimbi yakatetepa kana simbi ine simba rekudzivirira. Kazhinji nepepa kana tambo.

Zvinhu zvakapfava zvemagineti zvichishandiswa, nekuda kwekushanduka kwemagineti eddy zvinokonzereswa mukati mechinhu, zvichikonzera kurasikirwa, kuramba kwe alloy kudiki, ukobvu hwacho hunowedzera, frequency ye alternating magnetic field inowedzera, kurasikirwa kwe eddy current kuri kukuru, magnetic down yakawanda. Kuti izvi zviitike, chinhu chinofanira kugadzirwa pepa rakatetepa (tepi), uye pamusoro pacho pakafukidzwa ne insulating layer, kana kushandiswa kwemamwe maitiro pamusoro kuti pave ne oxide insulating layer, ma alloys akadaro anowanzo shandiswa magnesium oxide electrophoresis coating.

Iron-nickel alloy inonyanya kushandiswa panzvimbo imwe chete yemagineti, kunyanya pakushandisa majoko esimbi, relay, Small Power Transformers uye Magnetically shielded.

Kudzivirira magineti kwePermalloy: Kuti udzivise kupindira kwesimba remagineti rekunze, kazhinji muCRT, chikamu chekunze cheCRT electron beam focusing pamwe nekudzivirira magineti, unogona kuita basa rekudzivirira magineti.

| kuumbwa | C | P | S | Mn | Si |

| ≤ | |||||

| Zviri Mukati(%) | 0.03 | 0.02 | 0.02 | 0.3~0.6 | 0.15~0.3 |

| kuumbwa | Ni | Cr | Mo | Cu | Fe |

| Zviri Mukati(%) | 79.0~81.0 | - | 4.8~5.2 | ≤0.2 | Bhari |

Sisitimu yekurapa kupisa

| chiratidzo chechitoro | Annealing svikiro | tembiricha yekudziyisa | Chengeta nguva yekupisa/h | Mwero wekutonhora |

| 1j85 | Hydrogen yakaoma kana vacuum, kumanikidzwa hakupfuuri 0.1 Pa | Pamwe chete nechoto chinodziya kusvika 1100 ~ 1150ºC | 3~6 | Mu 100 ~ 200 ºC / h inotonhorera kusvika 600 ºC, nekukurumidza kusvika 300 ºC inodhonza chaji |

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro