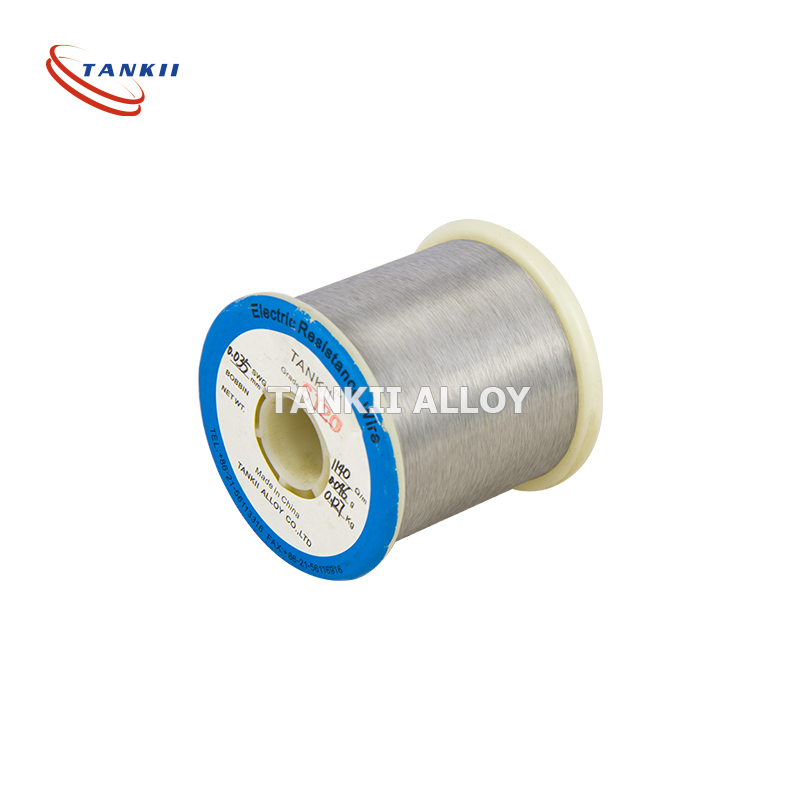

Ni90Cr10 NiCr 90/10 Nickel Chrome Alloy waya chrome Alumel Thermocouple Head Parts

Waya yeNi90Cr10 NiCr90/10 nickel chrome alloywaya ye nichromezvikamu zvemusoro zvethermocouple

mutengesi wechina nichrome 90 Ni90

Ni90Cr10 imhando ye austenitic nickel-chromium alloy (NiCr alloy) inoshandiswa pakupisa kusvika 1200°C (2190°F). Chiumbwa ichi chinoratidzwa nekusimba kwakanyanya, kuramba kuoxidation zvakanaka uye kugadzikana kwakanaka kwechimiro. Chine ductility yakanaka mushure mekushandiswa uye kugona kusundira zvakanaka.

Ni90Cr10 inoshandiswa pakugadzira zvinhu zvinodziya zvemagetsi mumidziyo yemumba nemaovheni emaindasitiri. Zvinowanzo shandiswa iaroni dzakatsetseka, michina yekuayina, maheater emvura, mapurasitiki ekuumba, simbi dzinosungirirwa, zvinhu zvesimbi zvine sheathed tubular uye zvinhu zve cartridge.

Nekuda kwehunhu hwakanaka hwekunamatira kwesurface oxide, Ni90C10 inopa hupenyu hwebasa hwepamusoro kana tichienzanisa nemakwikwi e nickel-chromium alloys.

| Zvinhu zvekushanda | Ni90Cr10 | Ni80Cr20 | Ni70Cr30 | Ni60Cr15 | Ni35Cr20 | Ni30Cr20 | |

| Kuumbwa | Ni | 90 | Zorora | Zorora | 55.0~61.0 | 34.0~37.0 | 30.0~34.0 |

| Cr | 10 | 20.0~23.0 | 28.0~31.0 | 15.0~18.0 | 18.0~21.0 | 18.0~21.0 | |

| Fe | ≤1.0 | ≤1.0 | Zorora | Zorora | Zorora | ||

| Tembiricha yepamusoroºC | 1300 | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Nzvimbo yekunyunguduka ºC | 1400 | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Kuwanda kwe g/cm3 | 8.7 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Kuramba kwesimba pa 20ºC((μΩ·m) | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.00±0.05 | 1.04±0.05 | ||

| Kureba pakubvaruka | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Kupisa kwakananga J/g.ºC | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | ||

| Kufambisa kwekupisa KJ/m.hºC | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | ||

| Kuwedzera kwemiganhu yekoefficient a×10-6/ (20~1000ºC) | 18 | 17 | 17 | 19 | 19 | ||

| Maumbirwo ema micrographic | Austenite | Austenite | Austenite | Austenite | Austenite | ||

| Hunhu hwemagineti | Isina magineti | Isina magineti | Isina magineti | Magineti asina simba | Magineti asina simba | ||

saizi:

OD: 0.3-8.0mm,

| Waya dzeKurwisa | ||

| RW30 | Nhamba yeW.Nr 1.4864 | Nickel 37%, Chrome 18%, Iron 45% |

| RW41 | UNS N07041 | Nickel 50%, Chrome 19%, Cobalt 11%, Molybdenum 10%, Titanium 3% |

| RW45 | Nhamba yeW.Nr 2.0842 | Nickel 45%, Copper 55% |

| RW60 | Nhamba yeW.Nr 2.4867 | Nickel 60%, Chrome 16%, Iron 24% |

| RW60 | UNS NO6004 | Nickel 60%, Chrome 16%, Iron 24% |

| RW80 | Nhamba yeW.Nr 2.4869 | Nickel 80%, Chrome 20% |

| RW80 | UNS NO6003 | Nickel 80%, Chrome 20% |

| RW125 | Nhamba yeW.Nr 1.4725 | Simbi BAL, Chrome 19%, Aruminiyamu 3% |

| RW145 | Nhamba yeW.Nr 1.4767 | Simbi BAL, Chrome 20%, Aruminiyamu 5% |

| RW155 | Simbi BAL, Chrome 27%, Aruminiyamu 7%, Molybdenum 2% | |

CHROMEL vs ALUMEL inoshandiswa mumhepo dzinopisa, dzisina simba kana dzakaoma. Kusangana ne vacuum kunogumira kwenguva pfupi. Inofanira kudzivirirwa kubva kumhepo dzine sulfure uye dzinopisa zvishoma. Yakavimbika uye yakarurama pakupisa kwakanyanya. Chromel: Chromel imhando ye 90% nickel uye 10% chromium. Inoshandiswa pakugadzira ma positive conductors e ANSI Type E neType K thermocouples, zvishandiso zvekuyera tembiricha ine ma conductor maviri akasiyana.

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro