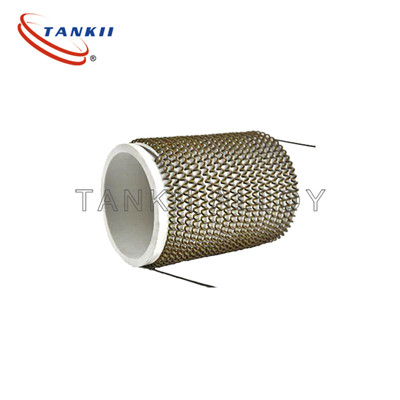

0Cr25Al5/Kant-hal A/alloy 835/KA Fecral alloy/Heating Wire/Furnace Spiral Heating Wire

0Cr25Al5 Fecral alloy/Heating Wire/Frace Spiral Heating Wire

1. Tsanangudzo

Iine maitiro ekupikisa kwepamusoro, yakaderera coefficient yemagetsi kuramba, Yakakwira tembiricha yekushanda, yakanaka corrosion resistance pasi pekushisa kwepamusoro.

Inonyanya kushandiswa mumagetsi locomotive, dhiziri locomotive, metro mota uye yakakwira Speed inofambisa mota etc brake system brake resistor, yemagetsi ceramic cooktop, indasitiri yevira.

2. Tsanangudzo

1). Locomotive resistance strip:

Ukobvu: 0.6mm-1.5mm

Upamhi: 60mm-90mm

2). Electric ceramic cooktop resistance strip:

Ukobvu: 0.04mm-1.0mm

Upamhi: 5mm-12mm

Ukobvu & Upamhi: (0.04mm-1.0mm) × 12mm (pamusoro)

3). Low resistance ribhoni:

Ukobvu & Upamhi: (0.2mm-1.5mm) * 5mm

4).Industrial chotoribhoni:

Ukobvu: 1.5mm-3.0mm

Upamhi: 10mm-30mm

3. Zvimiro

Kushanda kwakagadzikana; Anti-oxidation; Corrosion resistance; Kugadzikana kwekushisa kwepamusoro; Yakanakisa coil-kugadzira kugona; Uniform uye yakanaka pamusoro mamiriro pasina mavara.

4. Kurongedza zvakadzama

Spool, coil, kesi yemapuranga (sezvinodiwa nemutengi)

5. Zvigadzirwa uye masevhisi

1). Pass: ISO9001 certification, uye SO14001cetification;

2). Fine after-sale services;

3). Kurongeka kuduku kunogamuchirwa;

4). Yakagadzikana zvinhu mukupisa kwepamusoro;

5). Fast delivery;

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Zvimwe | ||

| Max | |||||||||||

| 0.12 | 0.025 | 0.025 | 0.70 | Max 1.0 | 13.0~15.0 | Hurefu 0.60 | 4.5~6.0 | Bal. | - | ||

Mechanical Properties

| Max Inopfuurira Service Temp | 980ºC |

| Resisivity pa20ºC | 1.28 ohm mm2/m |

| Density | 7.4 g/cm3 |

| Thermal Conductivity | 52.7 KJ/m@h@ºC |

| Coefficient of Thermal Expansion | 15.4×10-6/ºC |

| Melting Point | 1450ºC |

| Tensile Simba | 637~784 Mpa |

| Elongation | Zvishoma 12% |

| Chikamu Kusiyana Shrink Rate | 65~75% |

| Kasingaperi Bend Frequency | Min 5 nguva |

| Nguva Yebasa Inoenderera | - |

| Kuoma | 200-260HB |

| Micrographic Structure | Ferrite |

| Magnetic Property | Magnetic |

Temperature Factor yeMagetsi Resistivity

| 20ºC | 100ºC | 200ºC | 300ºC | 400ºC | 500ºC | 600ºC | 700ºC | 800ºC | 900ºC | 1000ºC |

| 1 | 1.005 | 1.014 | 1.028 | 1.044 | 1.064 | 1.090 | 1.120 | 1.132 | 1.142 | 1.150 |

Packaging Details:Delivery Delivery:

| Resistance heat 0Cr25AL5 waya kurongedza ruzivo: Purasitiki / spool, katoni, kesi yehuni, mudziyo |

| Iva nestock & kuburitsa kuramba kudziyisa 0Cr25AL5 waya |

Zvinotsanangurwa

0Cr25AL5 FeCrAl kuramba kupisa waya

1.Fe-Cr-Al chiwanikwa

2.GB/T 1234-95

3.Anti-oxidation

0Cr25AL5 FeCrAl kuramba kupisa waya

Iron-chromium-aluminium (FeCrAl) alloys

FeCrAl alloys inoratidzirwa neyakagwinyisa oxidation kuramba uye yakanaka kwazvo kugadzikana kwechimiro zvichikonzera hupenyu hurefu hwezvinhu. Iwo anowanzo shandiswa mumagetsi ekudziya zvinhu muchoto cheindasitiri uye midziyo yemumba.

FeCrAl alloys ane tembiricha yepamusoro sevhisi ipapo NiCr Alloys uye yakaderera mitengo.Asi ine yakaderera kugadzikana uye kuchinjika, nyore kuve isina kusimba mushure menguva denderedzwa.

Main mamakisi uye zvivakwa

| MaGrades | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Kemikari yakagadzirwa % | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| Fe | Balance | Balance | Balance | Balance | Balance | Balance | Balance | |

| Zvimwe | Nb 0.5 | Mo1.8-2.2 | ||||||

| Kunyanya kupisa kwesevhisi °C | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| ResistivityμΩ.M,20°C | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| Density (g/cm3) | 7.4 | 7.10 | 7.16 | 7.25 | 7.35 | 7.10 | 7.10 | |

| Thermal conductivity KJ/mH°C | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| Coefficient of linear extensibility Α×10-6/°C | 15.4 | 16.0 | 14.7 | 15.0 | 13.5 | 16.0 | 16.0 | |

| Kunyungudika °C | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Tensile Mpa | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| Elongation % | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Kuderedza % | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| Kuoma HB | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Microstructure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Zvigadzirwa zvikamu

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top