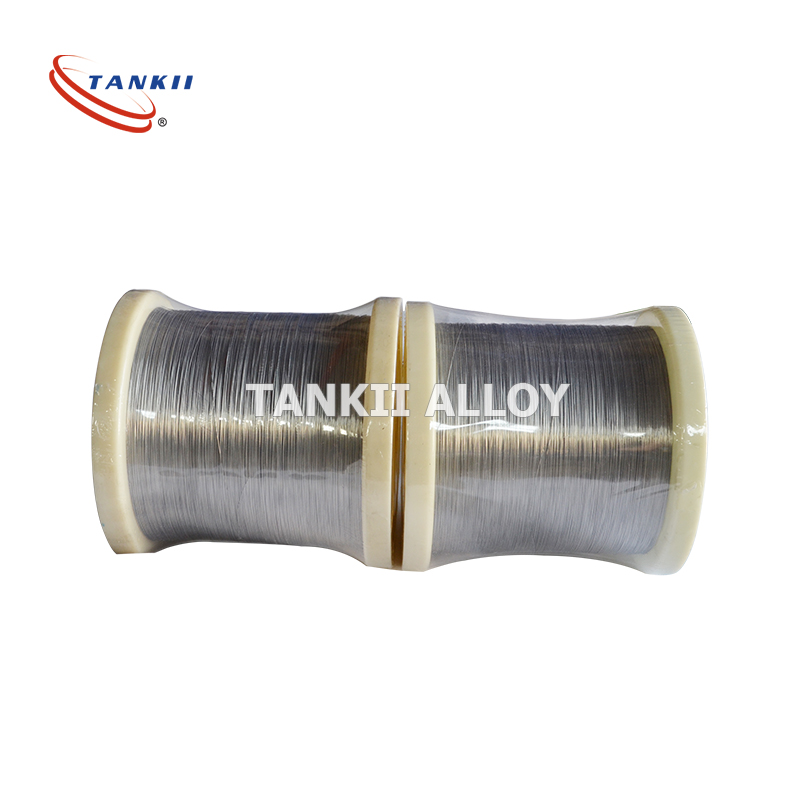

0Cr21Al4 Fecral Alloy Wire Acid White Soft Heating Resistance Wire

0Cr21Al4 Fecral Alloy Wire Acid White Soft Heating Resistance Wire

Tsanangudzo:

| Rudzi rwechiwanikwa | Dhayamita | Kuramba | Kusimba | Kureba (%) | Kukotama | Max. Kuenderera mberi | Kushanda Hupenyu |

| (mm) | (μΩm)(20°C) | Simba | Nguva | Basa | (maawa) | ||

| (N/mm²) | Tembiricha (°C) | ||||||

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

1) Magiredhi eAlloy:

OCr21Al4, OCr21Al6, OCr25Al5, OCr23Al5, 1Cr13Al4, OCr21Al6Nb, Cr15Ni60, Cr20Ni80, Cr30Ni70, Cr20Ni30 nezvimwewo.

Isu tiri vagadziri vehunyanzvi vepamusoro-soro vezvishandiso zvekupisa zvinodzivirira kupisa muChina, tichinyanya kugadzira Ferro-Chrome Alloys (Ferritic Alloys), Nickel-Chrome Alloys (Nichrome alloys), Copper Nickel Alloys (Constantan Alloys)

Muchimiro chewaya, ribhoni/mutsetse:

Waya Yakatenderera: Dia 0.04mm-8.0mm

Ribhoni/chidimbu: Ukobvu: 0.04mm-0.75mm

Upamhi: 0.08mm-6.0mm

2) Magadzirirwo eChigadzirwa:

Ferro-Chrome Alloys (Ferritic Alloys):

OCr21AL4, OCr21AL6, OCr25AL5, OCr23AL5, 1Cr13AL4, OCr21AL6Nb, OCr27AL7Mo2.

MaAlloys eNickel-Chrome (Ni-Cu Alloys):

Cr20Ni80, Cr15Ni60, Cr30Ni70, Cr20Ni30

Constantan Alloys (Cu-Ni Alloys):

CuNi1, CuNi2, CuNi6, CuNi8, CuNi10, CuNi14, CuNi19, CuNi23, CuNi30, CuNi44, Manganin.

3) Hunhu hwepamusoro hwakavimbiswa:

Mabasa edu ane hunyanzvi hwakakura hwekuita tekinoroji yepamusoro panyaya yekunyungudutsa, kutenderedza, kudhonza uye kupisa kusvika kuzvigadzirwa zvapera, pamwe chete nedhipatimendi rekuongorora makemikari, dhipatimendi rekuyedza physical uye dhipatimendi rekutonga mhando, tinotarisira zvigadzirwa zvedu kubva pazvinhu zvakagadzirwa kusvika kuzvigadzirwa zvekupedzisira.

4) Mashandisirwo: Zvinhu zvinopisa zvinodzivirira kupisa; Zvinhu zviri mukugadzira simbi; Midziyo yemumba; Kugadzira michina nemamwe maindasitiri.

5) Tinogona zvakare kupa zvimwe zvigadzirwa nekugadzira pamutengo wako: Waya yakamanikana, waya yakamonyoroka, waya yakamonerwa, waya dzakaita semafungu uye mhando dzakasiyana dzezvinhu zvemagetsi zvinodziya zvakajairwa kana zvisiri zvemazuva ose.

Iyo kambani Shanghai TANKII ALLOY MATERIAL Co., Ltd.

Mugadziri weFecral neAlchrome muChina, ndiye ane hunyanzvi hwakanyanya pasi rose

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro