0cr15al5 Bright Annealed Fecral Alloy Strip yeResistor

0cr15al5 Bright Annealed Fecral Alloy Strip yeResistor

Giredhi: 1Cr13AL4, 0Cr15AL5, 0Cr23AL5, 0Cr25AL5, 0Cr21AL6Nb0Cr27AL7Mo2

Saizi: Waya: 0.15~10mm

Bhawa: 12~120mm

| Zvivakwa/Giredhi | 1Cr13Al4 | 0Cr21Al4 | 0Cr21Al6 | 0Cr23Al5 | 0Cr25Al5 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Kemikari Huru kuumbwa (%) | Cr | 12.0-15.0 | 18.0-21.0 | 19.0-22.0 | 22.5-24.5 | 23.0-26.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 3.0-4.2 | 5.0-7.0 | 4.2-5.0 | 4.5-6.5 | 5.0-7.0 | 6.0-7.0 | |

| Fe | Kuenzana | Kuenzana | Kuenzana | Kuenzana | Kuenzana | Kuenzana | Kuenzana | |

| Re | mukana wakakodzera | mukana wakakodzera | mukana wakakodzera | mukana wakakodzera | mukana wakakodzera | mukana wakakodzera | mukana wakakodzera | |

| Nhamba:0.5 | Mwedzi:1.8-2.2 | |||||||

| Basa rinogara richienderera mberi tembiricha yechinhu | 950 | 1100 | 1250 | 1250 | 1250 | 1350 | 1400 | |

| Kuramba kuri pa20oC (μΩ @ m) | 1.25+-0.08 | 1.23+-0.06 | 1.42+-0.07 | 1.35+-0.07 | 1.42+-0.06 | 1.45+-0.07 | 1.53+-0.07 | |

| Kuwanda (g/cm3) | 7.4 | 7.35 | 7.16 | 7.25 | 7.1 | 7.1 | 7.1 | |

| Kufambisa kwekupisa (KJ/m@ h@ oC) | 52.7 | 46.9 | 63.2 | 60.2 | 46.1 | 46.1 | 45.2 | |

| Mutsetse wakakwana kuwedzera (α × 10-6/oC) | 15.4 | 13.5 | 14.7 | 15 | 16 | 16 | 16 | |

| Nzvimbo yekunyunguduka (inenge )(oC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Kureba pakutsemuka (%) | ≥16 | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 | ≥10 | |

| Maumbirwo ema micrographic | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| Hunhu hwemagineti | magineti | magineti | magineti | magineti | magineti | magineti | magineti | |

Nezve iyi alloy yemagetsi inodziya, tinogona kupa waya dzakasiyana-siyana, matanda, maplate, zvidimbu, tsvimbo, nezvimwewo.

Tsananguro

Iine hunhu hwekudzivirira kwakanyanya, kudzivirira kwemagetsi kwakaderera, tembiricha yepamusoro yekushanda, kudzivirira ngura kwakanaka pasi pekupisa kwakanyanya. Inonyanya kushandiswa mukubikira kwemagetsi kweceramic, muchoto cheindasitiri.

Kushandiswa

Inonyanya kushandiswa mumotokari dzemagetsi, mota dzedhiziri, mota dzemumugwagwa uye mota dzinofamba nekukurumidza nezvimwewo mabhureki system resistor, cooktop yemagetsi yeceramic, uye furnace yeindasitiri.

Zvinhu zvirimo

Kushanda kwakasimba; Kudzivirira oxidation; Kuramba ngura; Kugadzikana pakupisa kwakanyanya; Kugona kugadzira coil zvakanaka; Yakafanana uye yakanaka pamusoro pasina mavara.

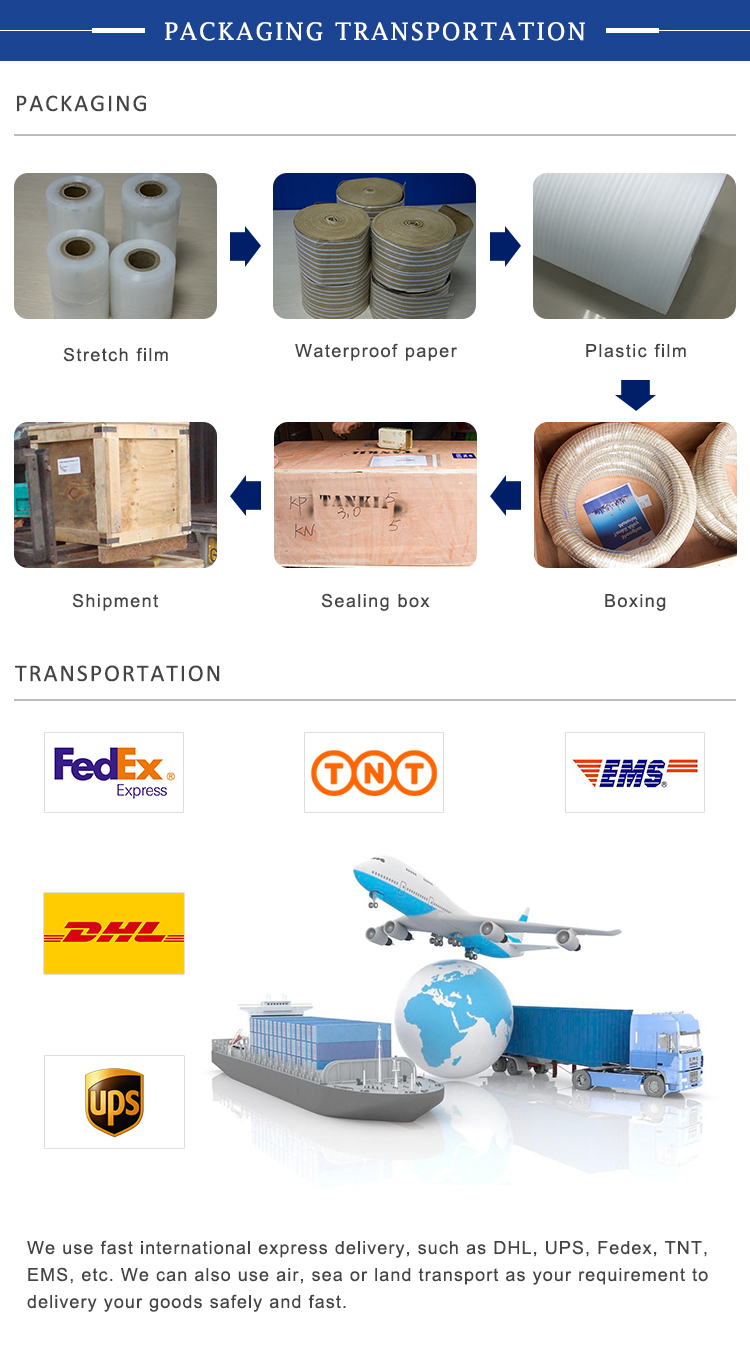

Ruzivo rwekurongedza

1) Koiri (purasitiki yakaputirwa) + bhokisi remapuranga rakamanikidzwa + pallet

2) Koiri (purasitiki inoputirwa) + katoni + pallet

Zvigadzirwa nemasevhisi:

1). Pasi: chitupa cheISO9001, uye SO14001certification;

2). Mabasa ekubhadhara faindi mushure mekutengesa;

3). Odha diki inogamuchirwa;

4). Hunhu hwakagadzikana kana tembiricha yakakwira;

5). Kutumirwa nekukurumidza;

.

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro