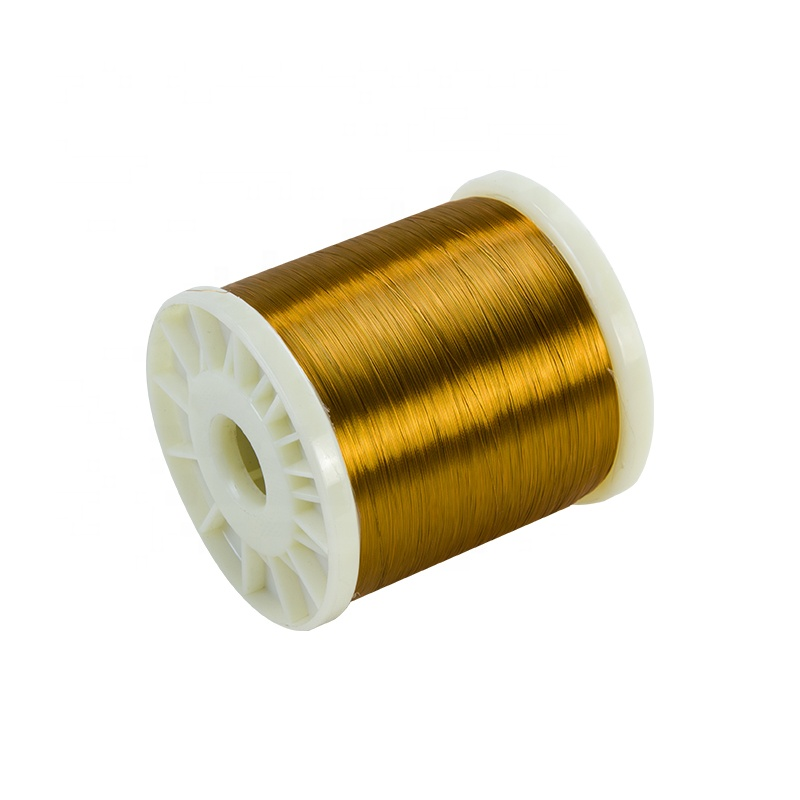

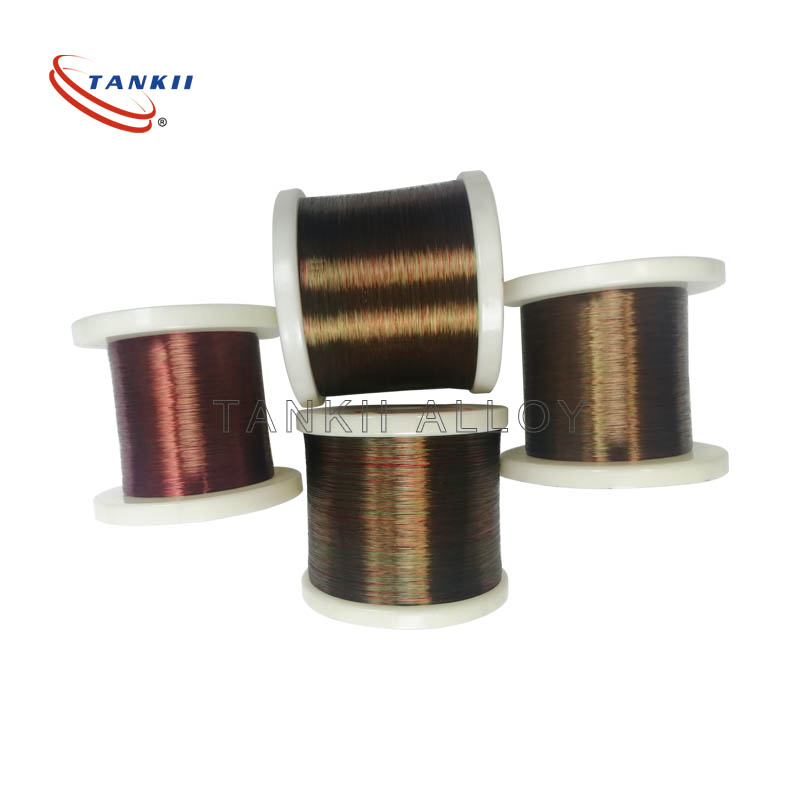

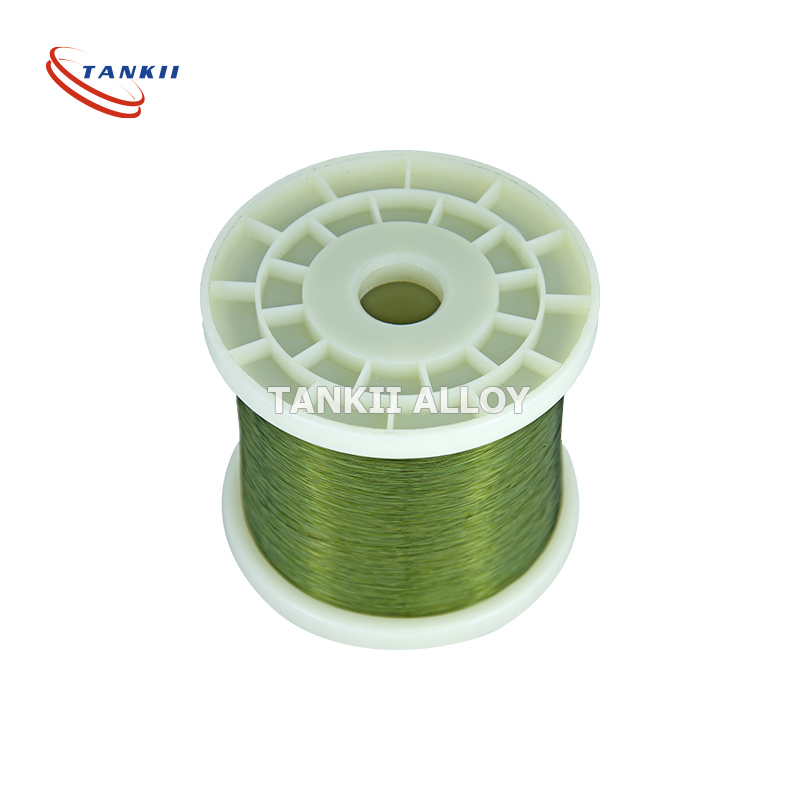

Waya yeEnameled yekirasi 0.2mm 130 ine ruvara rwakatenderera rwemhangura yeManganin

Waya ye130 Class Colored Round Copper Alloy Manganin Enameled

1. Tsananguro Yese Yezvinhu

Chiumbwa chenickel chemhangura, chine simba shoma rekudzivirira magetsi, hachipise kupisa uye hachiparadzi ngura, chiri nyore kugadzira uye chakasungirirwa ne lead. Chinoshandiswa kugadzira zvinhu zvakakosha mu thermal overload relay, thermal circuit breaker ine simba shoma, uye midziyo yemagetsi. Chinhu chakakoshawo pamagetsi ekupisa tambo. Chakafanana ne s type cupronickel. Nickel painoumbwa zvakanyanya, ndipo painochena sirivha yakawanda.

3.Kuumbwa kweChemical uye Hunhu Hukuru hweCu-Ni Low Resistance Alloy

| Grade yeZvivakwa | CuNi1 | CuNi2 | CuNi6 | CuNi8 | CuMn3 | CuNi10 | |

| Kuumbwa Kwemakemikari Main | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | Bhari | Bhari | Bhari | Bhari | Bhari | Bhari | |

| Tembiricha Yepamusoro Yebasa Rinoenderera Mberi (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Kusimba kwesimba pa20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Kuwanda (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Kufambisa kwekupisa (α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Simba reKusimba (Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Nzvimbo Inofungidzirwa Yekunyunguduka (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Maumbirwo eMicrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Pfuma yeMagineti | kwete | kwete | kwete | kwete | kwete | kwete | |

| Grade yeZvivakwa | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNi44 | |

| Kuumbwa Kwemakemikari Main | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | Bhari | Bhari | Bhari | Bhari | Bhari | Bhari | |

| Tembiricha Yepamusoro Yebasa Rinoenderera Mberi (oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Kusimba kwesimba pa20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Kuwanda (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Kufambisa kwekupisa (α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Simba reKusimba (Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Nzvimbo Inofungidzirwa Yekunyunguduka (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Maumbirwo eMicrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Pfuma yeMagineti | kwete | kwete | kwete | kwete | kwete | kwete | |

2. Nhanganyaya yeWaya Yakasanganiswa uye mashandisirwo ayo

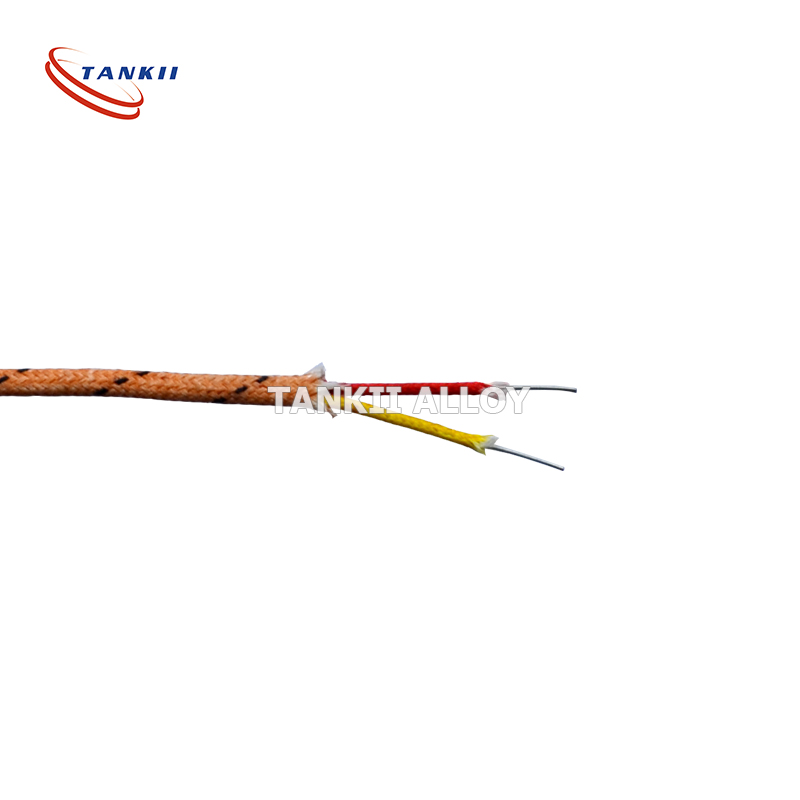

Kunyange zvazvo zvichitsanangurwa se "zvakaiswa enamel",waya ine enamelKutaura zvazviri, haina kuputirwa nependi ye enamel kana kuti ne vitreous enamel yakagadzirwa nehupfu hwegirazi hwakasanganiswa. Waya yemagineti yemazuva ano inowanzo shandisa jira rimwe kusvika mana (kana iri waya yemhando ye quad-film) ye polymer film insulation, kazhinji yemhando mbiri dzakasiyana, kupa jira rakasimba, rinogara richidzivirira. Mafirimu e magnet wire insulation anoshandisa (mukutevedzana kwekuwedzera kwekupisa) polyvinyl formal (Formar), polyurethane, polyimide, polyamide, polyamide, polyster, polyester-polyimide, polyamide-polyimide (kana amide-imide), uye polyimide. Waya yemagineti insulated polyimide inokwanisa kushanda kusvika 250 °C. Kudzivirira kwewaya yemagineti yakakora kana ye rectangular kunowanzo wedzerwa nekuiputira ne polyimide kana fiberglass tape ine tembiricha yepamusoro, uye ma windings akapedzwa anowanzo putirwa ne vacuum ne insulation varnish kuti ivandudze simba re insulation uye kuvimbika kwenguva refu kwe winding.

Makoiri anozvitsigira anoputirwa newaya yakafukidzwa nezvikamu zviviri, chikamu chekunze chiri thermoplastic inobatanidza matenderedzwa acho pamwe chete kana apiswa.

Mamwe marudzi ekudzivirira kupisa akadai seshinda yefiberglass ine varnish, bepa rearamid, bepa rekraft, mica, uye firimu repolyester anoshandiswawo zvakanyanya pasi rese mukushandiswa kwakasiyana-siyana senge ma transformer nema reactors. Muchikamu cheaudio, waya yesirivha yakagadzirwa, nezvimwe zvakasiyana-siyana zvinodzivirira kupisa, zvakaita sedonje (dzimwe nguva zvinozadzwa neimwe mhando ye coagulating agent/thickener, senge beewax) uye polytetrafluoroethylene (PTFE) zvinogona kuwanikwa. Zvinhu zvekare zvinodzivirira kupisa zvinosanganisira donje, bepa, kana sirika, asi izvi zvinongobatsira chete pakushandiswa kwekupisa kwakaderera (kusvika 105°C).

Kuti zvive nyore kugadzira, dzimwe waya dzemagineti dzine tembiricha yakaderera dzine insulation inogona kubviswa nekupisa kwekunamira. Izvi zvinoreva kuti kubatana kwemagetsi kumagumo kunogona kuitwa pasina kubvisa insulation kutanga.

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro