Kugamuchirwa kumawebhusaiti edu!

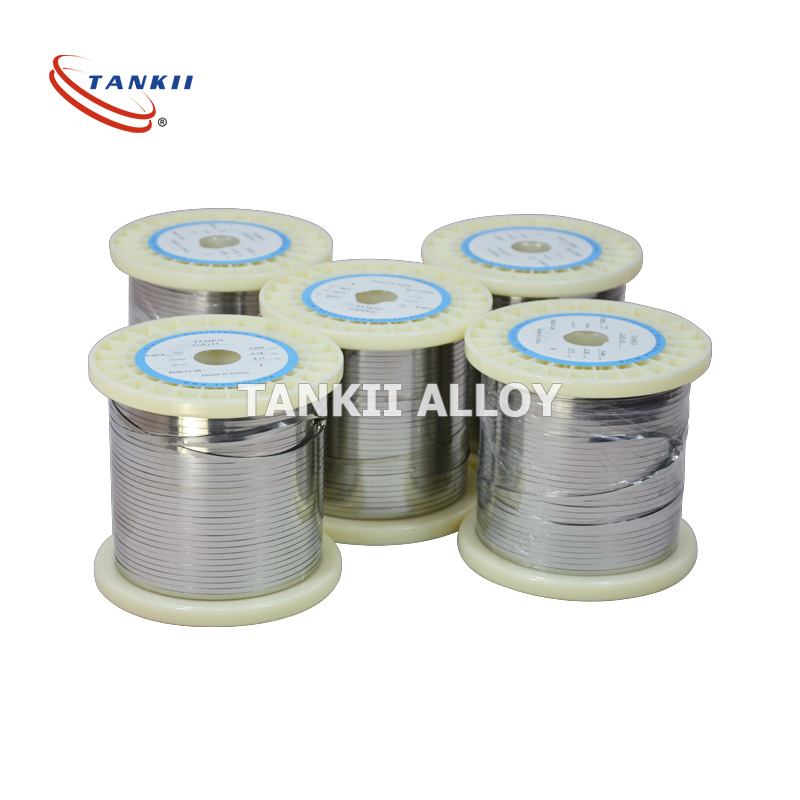

0.25mm 0Cr25Al5 Bright Wire kune Industrial Furances

Basic Info.

| Parameter | Details | Parameter | Details |

|---|---|---|---|

| Muenzaniso NO. | 0cr25al5 | Kuumbwa Kwemakemikari | 0cr25al5 |

| Product Name | Heating Resistance Strip | Hunhu | High Resistivity, Zvakanaka Oxidation Resistance |

| The Highest Use Temperature | 1300 ℃ | Density | 7.1g/cm³ |

| Resisivity | 1.42 Ω·m | Elongation | >20% |

| Muenzaniso | Support | Transport Package | Wooden Cases kana Cartons |

| Tsanangudzo | 0.25mm | Trademark | Tankii |

| Origin | Jiangsu | HS Code | 7408220000 |

| Kukwanisa Kugadzira | 100 Matani / Mwedzi |

Product Description

0.25mm 0cr25al5 Kupisa Fecral Alloy Wire yeIgnition tambo General Description FeCrAl alloy yakagadzirwa nepamusoro-tembiricha, ferritic iron-chromium-aluminium alloy iyo inogona kushandiswa pakupisa kusvika ku1350degrees. Mashandisirwo akajairika eFeCrAl akafanana nemagetsi ekudziisa zvinhu mumavira anopisa kwazvo mukupisa kupisa, ceramics, girazi, simbi, uye maindasitiri emagetsi. Feature: Nehupenyu hurefu hwebasa.Kupisa nekukurumidza.Kupisa kwekushisa kwakanyanya.Kupisa kufanana. Inogona kushandiswa vertically. Kana ichishandiswa muyakayerwa voltage, hapana chinhu chinoputika.Iri kuchengetedzwa kwezvakatipoteredza magetsi ekupisa waya. Uye imwe nzira kune inodhura nichrome waya. Inogona kugadzirwa maererano nezvinodiwa nevatengi FeCrAl alloys inoratidzirwa nekunakisisa oxidation kuramba uye yakanaka kwazvo fomu kugadzikana zvichikonzera hupenyu hurefu hwezvinhu. Iwo anowanzo shandiswa mumagetsi ekudziya zvinhu mumaindasitiri echoto uye midziyo yemumba. Fe-Cr-Al alloy ine yakakwirira resistivity uye sevhisi tembiricha kupfuura iyo yeNiCr alloy uye zvakare ine yakaderera mutengo. Applications Iron-chrome-aluminium electric resistor wire inoshandiswa zvakanyanya kugadzira magetsi ekudziya zvinhu mumidziyo yemumba nemavira emaindasitiri. Mashandisirwo akajairika simbi dzakatsetseka, michina yekuayina, hita dzemvura, kuumbwa kwepurasitiki kunofa, simbi dzekutengesa, simbi sheathed tubular zvinhu uye cartridge zvinhu. Nzvimbo yekushandisa Zvigadzirwa zvedu zvinoshandiswa zvakanyanya mukupisa kupisa michina, auto zvikamu, iron uye simbi kugadzira, aruminiyamu indasitiri, metallurgical midziyo, petrochemical midziyo, girazi michina, zvedongo muchina, muchina wechikafu, mishonga yemishonga, uye simba reinjiniya indasitiri. Chemical Content,%

Hunhu hwehunyanzvi hunhu hweFeCrAl Alloy:

| Alloy zvinhu | Kemikari yakagadzirwa % | |||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | vamwe | |

| hukuru(≤) | ||||||||||

| 1Cr13Al4 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 12.5-15.0 | - | 3.5-4.5 | Zorora | - |

| 0Cr15Al5 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 14.5-15.5 | - | 4.5-5.3 | Zorora | - |

| 0Cr25Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 23.0-26.0 | ≤0.60 | 4.5-6.5 | Zorora | - |

| 0Cr23Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 20.5-23.5 | ≤0.60 | 4.2-5.3 | Zorora | - |

| 0Cr21Al6 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 19.0-22.0 | ≤0.60 | 5.0-7.0 | Zorora | - |

| 0Cr19Al3 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 18.0-21.0 | ≤0.60 | 3.0-4.2 | Zorora | - |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.60 | 21.0-23.0 | ≤0.60 | 5.0-7.0 | Zorora | Nb wedzera0.5 |

| 0Cr27Al7Mo2 | 0.05 | 0.025 | 0.025 | 0.2 | ≤0.40 | 26.5-27.8 | ≤0.60 | 6.0-7.0 | Zorora | |

| BrandProperty | 1Cr13Al4 | 1Cr21Al4 | 0Cr21Al6 | 0Cr23Al5 | 0Cr25Al5 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Chikamu chikuru chemakemikari% | Cr | 12.0-12.5 | 17.0-21.0 | 19.0-22.0 | 20.5-23.5 | 23.0-26.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 2.0-4.0 | 5.0-7.0 | 4.2-5.3 | 4.5-6.5 | 5.0-7.0 | 6.0-7.0 | |

| Fe | Balance | Balance | Balance | Balance | Balance | Balance | Balance | |

| Re | Zvakakodzera | Zvakakodzera | Zvakakodzera | Zvakakodzera | Zvakakodzera | Zvakakodzera | Zvakakodzera | |

| Kuwedzera Nb: 0.5 | AdditionMo:1.8-2.2 | |||||||

| Component max. shandisa tembiricha | 950 | 1100 | 1250 | 1250 | 1250 | 1350 | 1400 | |

| Melting Point | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1510 | |

| Density g/cm3 | 7.40 | 7.35 | 7.16 | 7.25 | 7.10 | 7.10 | 7.10 | |

| Kuramba μΩ·m,20 | 1.25±0.08 | 1.23±0.06 | 1.42±0.07 | 1.35±0.06 | 1.45±0.07 | 1.45±0.07 | 1.53±0.07 | |

| Tensile Simba Mpa | 588-735 | 637-784 | 637-784 | 637-784 | 637-784 | 637-784 | 684-784 | |

| Extension rate% | 16 | 12 | 12 | 12 | 12 | 10 | ||

| Kudzokororwa kubhenda frequency | 5 | 5 | 5 | 5 | 5 | |||

| Kusimudza nekukurumidza h/ | - | 80/1300 | 80/1300 | 50/1350 | ||||

| Chaicho Kupisa J/g. | 0.490 | 0.490 | 0.520 | 0.460 | 0.494 | 0.494 | 0.494 | |

| Heat Conduction Coefficient KJ/Mh | 52.7 | 46.9 | 63.2 | 60.1 | 46.1 | 46.1 | 45.2 | |

| Linear yekuwedzera coefficient aX10-6/(20-1000) | 15.4 | 13.5 | 14.7 | 15.0 | 16.0 | 16.0 | 16.0 | |

| Kuoma HB | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Microstructure | Ferritic | Ferritic | Ferritic | Ferritic | Ferritic | Ferritic | Ferritic | |

| Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Nyora meseji yako pano uye titumire kwatiri

Zvigadzirwa zvikamu

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top