Tinokugamuchirai kumawebhusaiti edu!

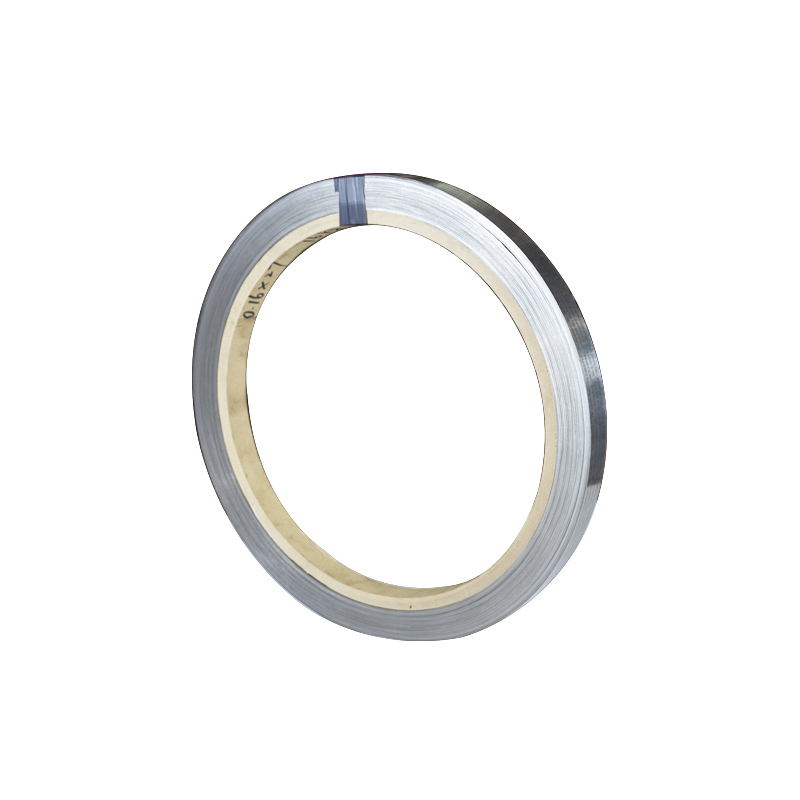

0.16mm x 27mm P675R/TM2/TB20110 Bimetallic Strip ASTM B388 Kukurumidza Kupindura uye Kugara Kwenguva Refu

Tsananguro yeChigadzirwa

P675R Bimetallic Strip (0.16mm Ukobvu × 27mm Upamhi)

Pfupiso yeChigadzirwa

P675R bimetallic strip (0.16mm×27mm), chinhu chinoshanda chakagadzirwa nemazvo kubva kuTankii Alloy Material, imhando yecomposite strip yakagadzirwa nema alloys maviri akasiyana ane ma coefficients akasiyana ekuwedzera kwekupisa - akabatanidzwa zvakasimba kuburikidza netekinoroji yedu yekubatanidza kupisa nekupararira. Iine gauge yakatetepa ye0.16mm uye upamhi hwakajairika hwe27mm, iyi strip yakagadzirirwa kushandiswa kwema miniaturized tembiricha-sensitive applications, uko kunyatsoshanda kwekupisa, stable dimensionality, uye dhizaini yekuchengetedza nzvimbo zvakakosha. Ichishandisa hunyanzvi hwaHuona mukugadzirisa bimetallic composite, P675R grade inopa kushanda kwakasimba kwekuchinja kwekushisa, ichipfuura bimetallic strips generic mu micro-device compatibility uye kuramba kuneta kwenguva refu - zvichiita kuti ive yakakodzera ma compact thermostats, overheat protectors, uye precision tembiricha compensation components.

Mazita Akajairwa & Kuumbwa Kwakakosha

- Giredhi reChigadzirwa: P675R

- Kutsanangurwa kweDimensional: 0.16mm ukobvu (kushivirira: ± 0.005mm) × 27mm upamhi (kushivirira: ± 0.1mm)

- Maumbirwo eComposite: Kazhinji ine "chikamu chekuwedzera chakakwirira" uye "chikamu chekuwedzera chakaderera", chine simba rekuchekerera pakati pechiso ≥160 MPa

- Mitemo Inotevedzera: Inotevedzera GB/T 14985-2017 (chiyero cheChinese chemitsetse ye bimetallic) uye IEC 60694 yezvinhu zvinodzora kupisa

- Mugadziri: Tankii Alloy Material, ine chitupa cheISO 9001 neISO 14001, ine kugona kupinza zvinhu zvakasanganiswa zvakanaka mukati meimba uye kupatsanura nemazvo.

Mabhenefiti Akakosha (zvichienzaniswa neGeneric Thin-Gauge Bimetallic Strips)

Chidzitiro cheP675R (0.16mm×27mm) chinosiyanisa mashandiro acho nekushanda kwacho kwakatetepa uye nyore kushandisa hupamhi hwacho:

- Kugadzikana Kwakatetepa Zvikuru: Kuchengetedza ukobvu hwakafanana (0.16mm) uye hapana kucheka kwepakati pechiso—kunyangwe mushure me5000 thermal cycles (-40℃ kusvika 180℃)—kugadzirisa dambudziko rinowanzoitika rekuti thin-gauge bimetallic strips (≤0.2mm) dzinokanganisa kupatsanurwa kana kupatsanurwa kwelayer.

- Kushanda Kwekupisa Kwakanyatsonaka: Kudzora 温曲率 (kukombama kunokonzerwa nekupisa) kwe9-11 m⁻¹ (pa100℃ vs. 25℃), nekutsauka kwekupisa kwekushanda ≤±1.5℃—kukosha kune zvishandiso zvidiki (semuenzaniso, zvinodzivirira kupisa zvakanyanya zvebhatiri diki) uko miganho yekupisa yakamanikana.

- Upamhi Hwakagadziriswa hweKugadzira Otomatiki: Upamhi hwakajairika hwe27mm hunoenderana nehukuru hwemadhiyi akajairika e-micro-stamping, zvichibvisa kudiwa kwekuchekwa kwechipiri uye kuderedza marara ezvinhu ne ≥15% zvichienzaniswa nezvidimbu zvehupamhi hwecustom-width.

- Kugona Kugadzira: Gauge yakatetepa ye0.16mm inoita kuti zvive nyore kukotama (radius yekukotama ≥2× ukobvu) uye kucheka nelaser kuita ma micro-shapes (semuenzaniso, thermostat contacts diki) pasina kutsemuka—inoenderana nemitsetse yekuunganidza inomhanyisa otomatiki.

- Kuramba Kuora: Kurapa kwekusagona kupora pamusoro pechinhu kunopa simba rekudzivirira kupfapfaidza munyu kwemaawa makumi manomwe nemaviri (ASTM B117) pasina ngura dzvuku, zvakakodzera munzvimbo dzine hunyoro (semuenzaniso, sensors dzekupisa dzemidziyo inopfekwa).

Magadzirirwo ehunyanzvi

| Hunhu | Kukosha (Kwakajairika) |

|---|---|

| Ukobvu | 0.16mm (kushivirira: ± 0.005mm) |

| Upamhi | 27mm (kushivirira: ± 0.1mm) |

| Kureba paRoll | 100m – 300m (yakachekwa kusvika pakureba iripo: ≥50mm) |

| Chiyero chekuwedzera kwemafuta (Chikamu chepamusoro/chakaderera) | ~13.6:1 |

| Kushanda Tembiricha Range | -70℃ kusvika 350℃ |

| Rated Actuation Temperature Range | 60℃ – 150℃ (inogadziriswa kuburikidza nekugadzirisa chiyero che alloy) |

| Simba reKucheka reInterfacial | ≥160 MPa |

| Simba Rekusimba (Kuchinjika) | ≥480 MPa |

| Kureba (25℃) | ≥12% |

| Kuramba (25℃) | 0.18 – 0.32 Ω·mm²/m |

| Kuoma Kwepamusoro (Ra) | ≤0.8μm (kupedzisa kwemugayo); ≤0.4μm (kupedzisa kwakakweshwa, sarudzo) |

Zvimiro zveChigadzirwa

| Chinhu | Tsanangudzo |

|---|---|

| Kupedzisa Kwepamusoro | Kupedzisa kwemugayo (isina oxide) kana kupedzisa kusina ngura (yekudzivirira ngura) |

| Kufara | ≤0.08mm/m (zvakakosha pakuita kuti zvidimbu zvinyatsogadzirwa zvakanaka) |

| Hunhu hwekubatana | 100% interfacial bonding (hapana ma voids >0.05mm², yakasimbiswa kuburikidza ne X-ray inspection) |

| Kugona kutengeswa | Kuisa tin-plating (ukobvu: 3-5μm) kune mukana wekuwedzera kuchinjika kwesimbi uchishandisa Sn-Pb/lead-free solders. |

| Kurongedza | Yakavharirwa mupurasitiki mumabhegi ealuminium foil anodzivirira kuoxidation ine desiccants; mapurasitiki (150mm dhayamita) kudzivirira kushanduka kwemavara |

| Kugadzirisa | Kugadziriswa kwekupisa kwemagetsi (30℃ - 200℃), kufukidza pamusoro (semuenzaniso, nickel-plating), kana maumbirwo akatoiswa stampu (pamafaira eCAD emutengi) |

Maitiro Akajairika

- Kudzora Tembiricha Yakabatana: Micro-thermostat yemidziyo inopfekwa (semuenzaniso, mawachi akangwara), midziyo midiki yemumba (semuenzaniso, mamini rice cooker), uye midziyo yekurapa (semuenzaniso, insulin coolers).

- Dziviriro yekupisa zvakanyanya: Zvishandiso zvemagetsi zvemabhatiri e-lithium-ion (semuenzaniso, mabhangi emagetsi, mabhatiri e-earbud asina waya) uye ma-micro-motors (semuenzaniso, ma-drone motors).

- Kubhadhariswa Kwakarurama: Kubhadhariswa kwekupisa kwemasensa eMEMS (semuenzaniso, masensa ekumanikidza mumafoni) kuti agadzirise zvikanganiso zvekuyera kupisa zvinokonzerwa nekuwedzera kwesimba.

- Magetsi Emagetsi Evatengi: Magadzirirwo ekupisa ekugadzirisa mwenje we backlight welaptop uye magadzirirwo ekupisa eprinta fuser.

- Zvishandiso Zvidiki zveIndasitiri: Zvishandiso zvidiki zvekupisa zvemasensa eIoT (semuenzaniso, masensa ekupisa/hunyoro epamba) uye zvinhu zvidiki zvemotokari (semuenzaniso, mamonita ekupisa ehurongwa hwemafuta).

Tankii Alloy Material inoshandisa zvidimbu zveP675R bimetallic strips (0.16mm×27mm) kuti iongororwe zvakanaka: bvunzo dze interfacial bonding shear, bvunzo dze thermal stability tests dze 1000-cycle, dimensional inspection via laser micrometry, uye actuation temperature calibration. Samples dzemahara (50mm×27mm) uye mishumo yakadzama yekushanda (kusanganisira 温曲率 vs. temperature curves) zviripo kana zvakumbirwa. Chikwata chedu chehunyanzvi chinopa rutsigiro rwakagadzirirwa iwe—senge alloy layer optimization ye specific actuation temperatures uye micro-stamping process guidelines—kuona kuti strip inosangana nezvinodiwa chaizvo zve compact, precision-driven applications.

Nyora meseji yako pano woitumira kwatiri

Zvikamu zvezvigadzirwa

-

Runhare

-

E-mail

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Pamusoro